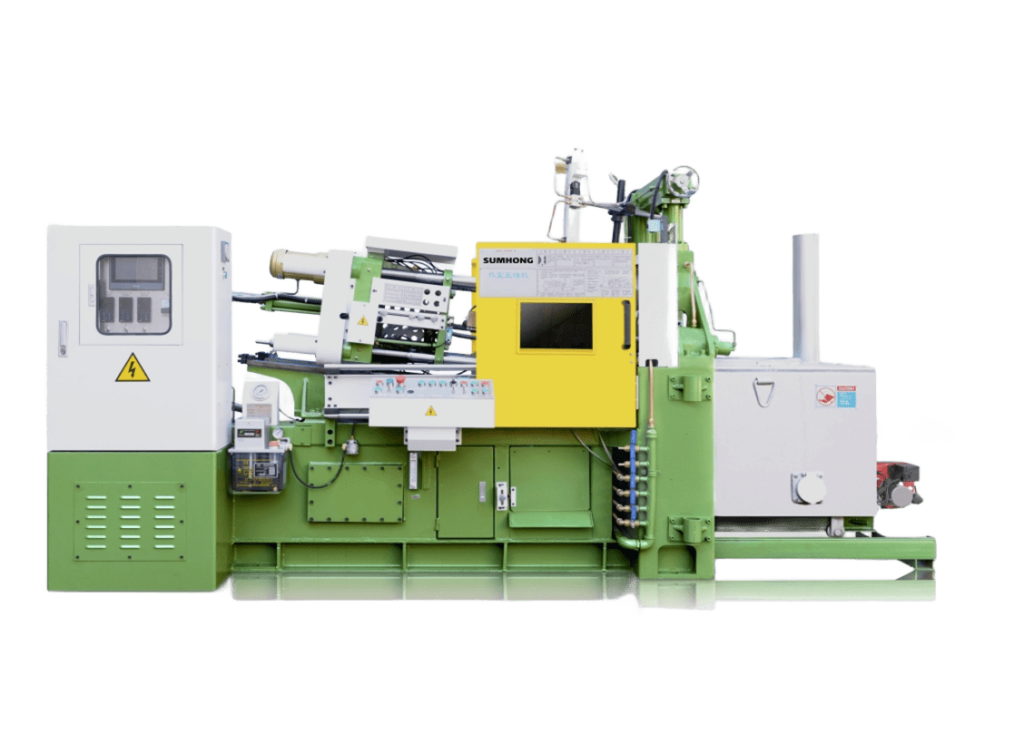

SH-Series Hot Chamber Die Casting Machine

User-Friendly

Easy-to-use interactive system

High-Performance

Up to 40% with innovative hydraulic.

Advanced Technology

Intelligent real-time control system

Durable & Reliable

Long-lasting Operational Lifespan

Die Cast Machines Performance Advantages

Hydraulic Unit

– Premium Hydraulic Components: The system incorporates hydraulic components from renowned global brands, ensuring high-quality performance and reliability.

– High-Speed Injection: The specially designed squeezing and injection system, combined with a piston-type power accumulator, delivers rapid injection speed and powerful force for optimal die-casting results.

– Strong Force & Precision: The hydraulic system provides the necessary strength and precision for complex injection processes, improving production efficiency and product quality.

Clamping Unit

– High Precision Clamping: The mould board and reamer are made from spheroidal graphite cast iron and are processed with high-precision CNC machining, ensuring accurate mould clamping.

-Strong Clamping Force: A large chromium-plated bar provides excellent tensile strength and hardness, offering ample space for moulds of various sizes and enhancing the clamping power.

-Low-Pressure Mould Protection: The mould is equipped with a protective device against low pressure, safeguarding against potential damage during operation.

-Automatic Pillar Support: The pillar support moves backward or forward automatically, ensuring smooth mould adjustments.

-Flexible Die Casting Modes: The system offers both fixed and traverse die-casting modes for greater versatility.

-Fast & Automatic Operation: The slating mould clamping system facilitates quick, automatic adjustments, boosting efficiency and reducing manual intervention.

Injection Unit

The injection unit is equipped with high-quality components, including a nozzle, plunger, steel piston ring, and goose neck, all made from premium steel materials from renowned brands. These high-performance materials ensure long-term, stable operation even under high temperature and pressure conditions.

Key features:

– Durability & Stability: Manufactured with top-tier steel, the injection unit is designed to withstand harsh conditions, ensuring reliable and consistent performance.

– Versatile Heating Options: Choose from diesel, electrical heating, or coke melting methods, offering flexibility for different operational needs.

-Efficient Temperature Control: Electrical heating at the nozzle and goose neck maintains stable temperature control, supporting optimal performance and preventing overheating over extended periods.

Electrical Control System

– Stable Operation: OMRON computers are integrated to guarantee consistent performance even under challenging conditions, ensuring the system remains stable and reliable.

– Safety & Low Fault Rate: A 24V DC system is implemented to enhance safety and reduce fault rates, contributing to higher operational reliability and less downtime.

– User-Friendly Interface: The intuitive display allows easy parameter adjustments and provides prompts in case of any faults, simplifying operation and improving user experience.

– Precise Temperature Control: The nozzle, goose neck, and melting pot are equipped with numerically controlled thermometers to maintain stable and accurate temperature regulation throughout the process.

– Reduced Fault Risk: The proximity stroke switch helps minimize the fault rate by detecting issues early, ensuring smoother and more reliable operation.

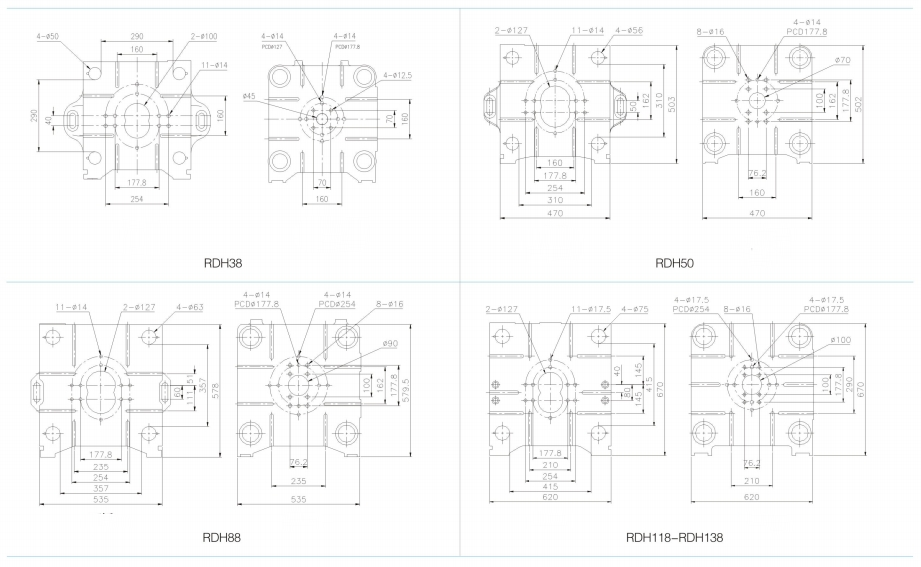

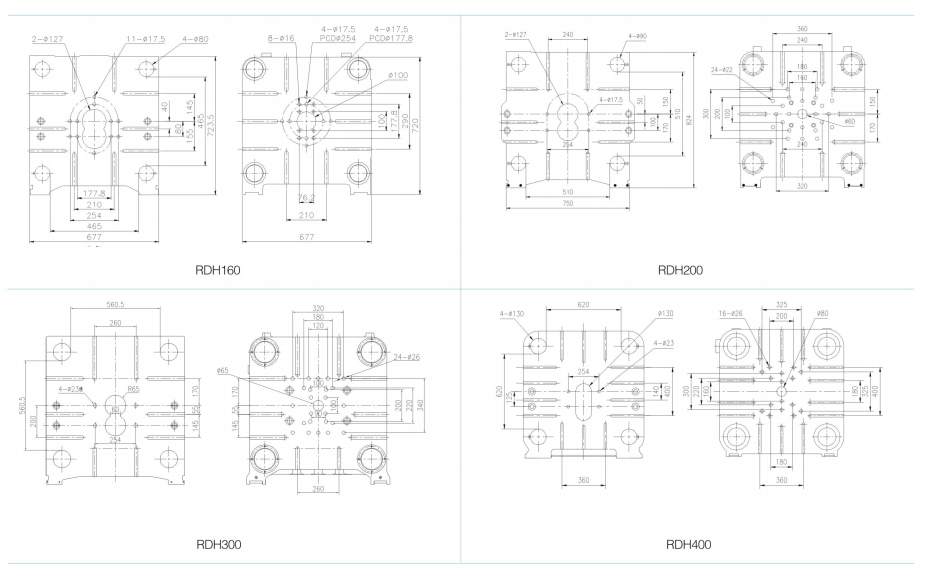

Mold Platen Layout

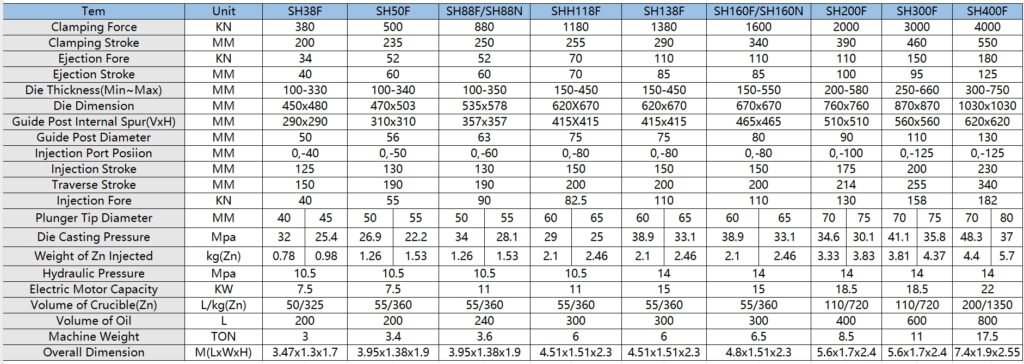

Specification

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.