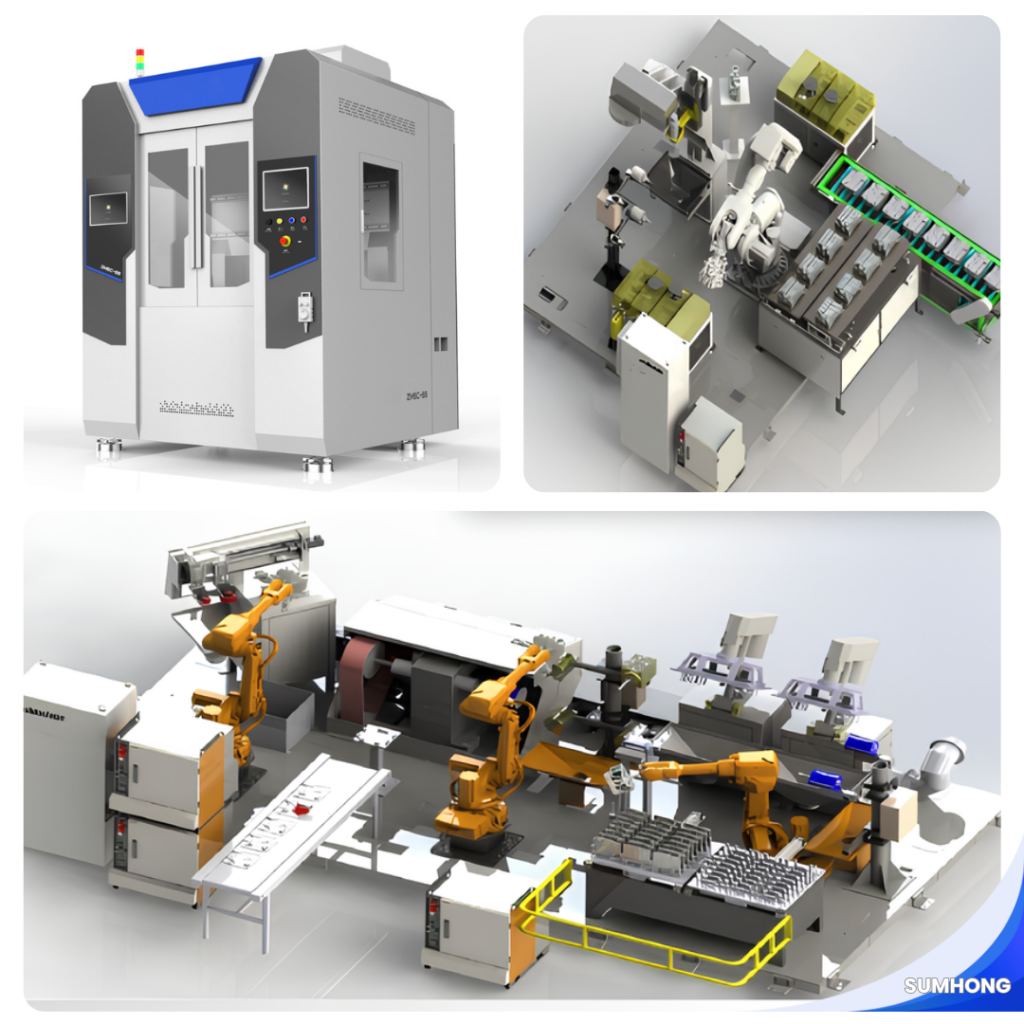

Metal Deburring Machine-Omron

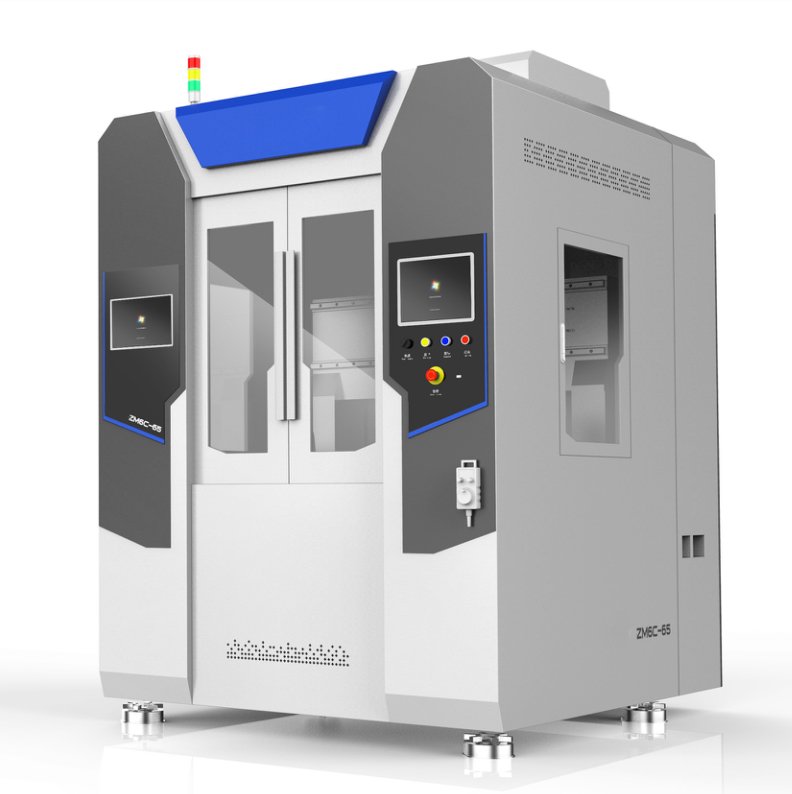

We use advanced metal deburring machine to ensure that each deburring machine meets the highest industry standards. Features include:

High-Performance Multi-Axis Control System

Powered by Omron’s multi-axis control system, providing precise and stable control with smooth motion.

Omron Servo Motor

Equipped for rapid response, delivering a smooth operational path with exact position control.

Robust Construction

The main structure is crafted with cast iron mold-opening technology, ensuring high rigidity, precision, and stability without tool vibration. It is optimized for fast feed speeds, making it an ideal machine for both grinding and deburring.

User-Friendly System

The system can store thousands of programs, enabling quick recall when switching products, which reduces programming time and increases facility utilization.

Efficient accurate reliable

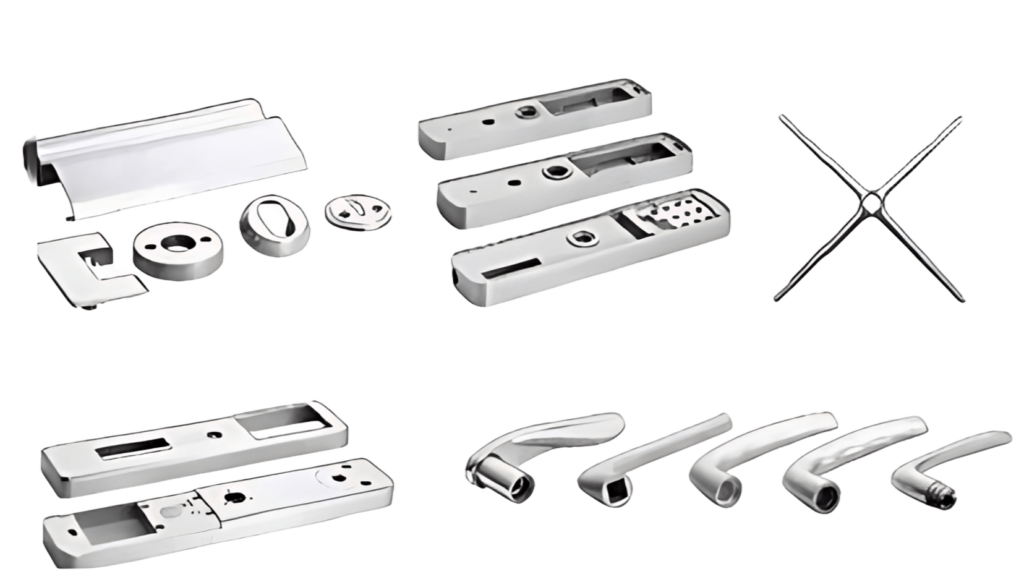

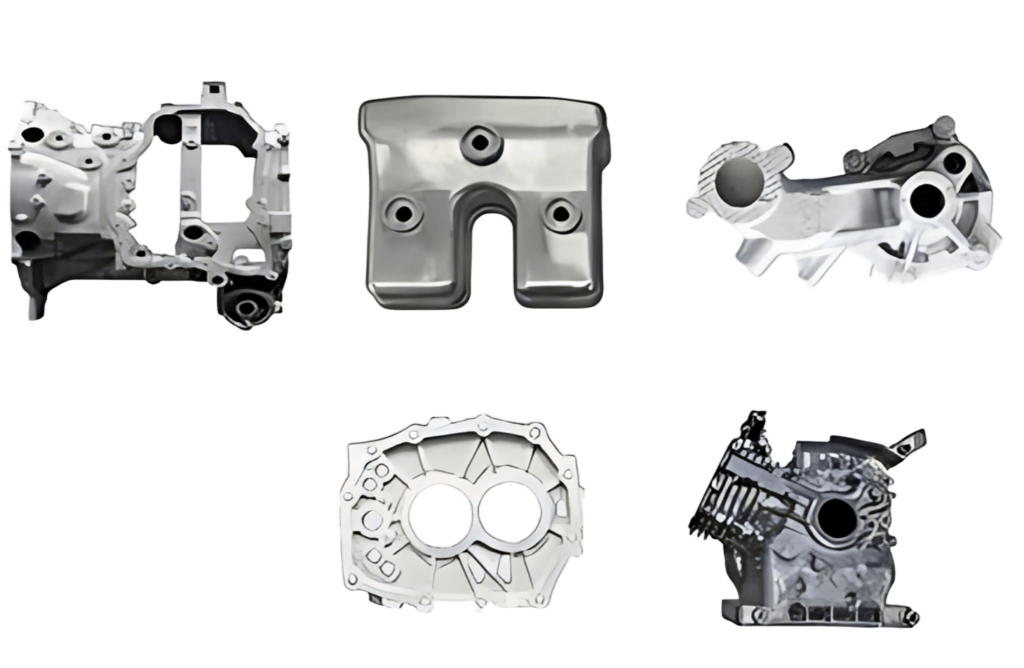

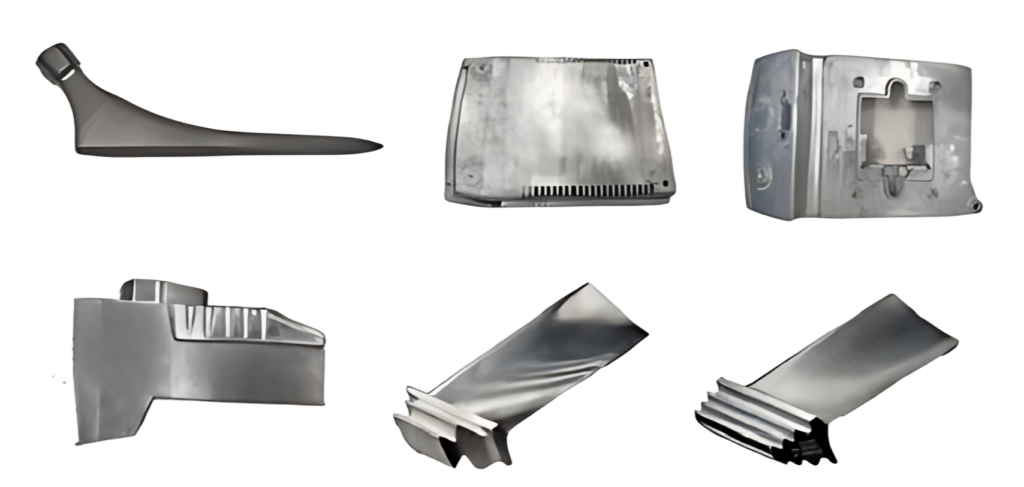

We provide professional deburring machine solutions for multiple industries

SUMHONG offers automated deburring machine and polishing control systems for a wide range of industries, including bathroom and kitchen products, automotive parts, construction hardware, sports equipment, medical devices, home furnishings, military weapons, and aerospace. With extensive experience and a clear advantage in robotic polishing, deburring, and burr removal。

Metal Deburring Machine-Omron

Performance Advantages

High-Precision Deburring Machine for Die-Casting Operations with Multi-Axis Control

Six-Axis Intelligent Grinding

Capable of movement along the X, Y, and Z axes, with rotational capabilities around the A, B, and C axes. This enables multi-directional grinding in a single setup.

Flexible Six-Head Rotary Tool Library

This design allows rapid tool changes without returning to a fixed tool-change position, improving tool change efficiency and enabling multi-angle processing.

Quick-Change Worktable Setup

Equipped with a quick-change locating pin for fast tooling switch-outs, significantly reducing setup and debugging time.

Automatic Tool Compensation

Extends the lifespan of grinding tools, reducing wear and tear for enhanced durability.

Optimized for Die-Casting Operations

Designed for use alongside die-casting machines, it supports integrated automated operations and can also be manually operated by a single individual across multiple machines.

Adaptable Tooling Options

The machine offers flexible tool replacements to accommodate various grinding requirements, combining flexible and rigid tools for optimal performance.

- Precision flexible control system

- Parameterized closed-loop control system

- Abrasive and position compensation system

- Automatic Dimension and Displacement Detection System

- Automatic tool and consumable change system

- Automatic Tool Library System

- Standard Consumables Process Database

- Automatic chip removal systems

- Dust and sound proofing safety systems

- learn more

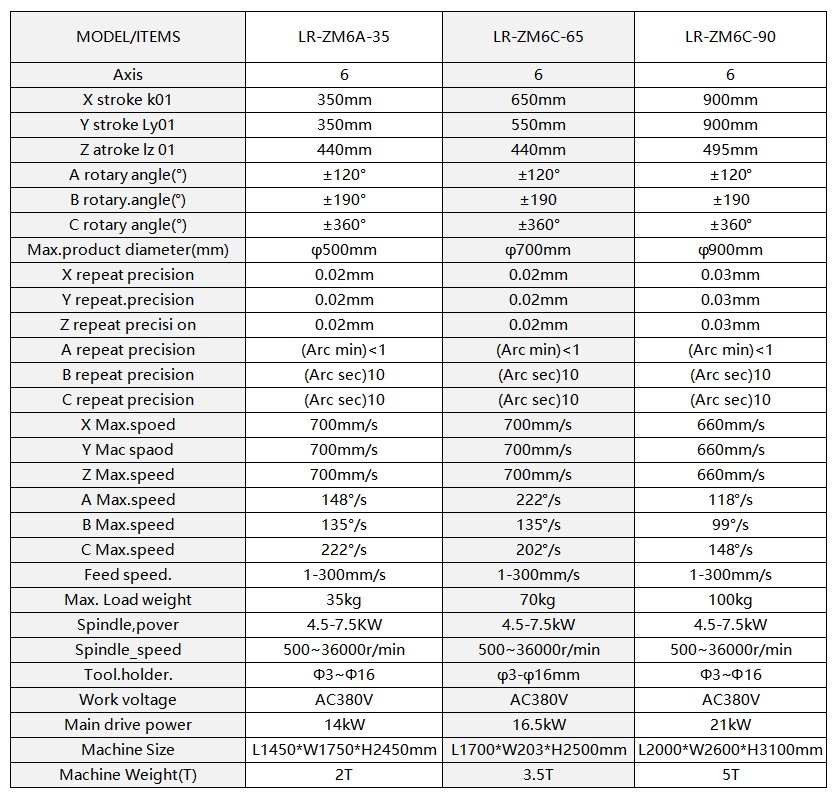

Equipment parameters

See What Our Customers Ask Frequently

We provide detailed answers to some questions you may have

What materials are our deburring machines suitable for?

Our deburring machines can efficiently process a wide range of materials, including metals, plastics and composites, ensuring they meet the needs of a wide range of industries.

How long does it take to maintain a deburring machine?

Our deburring machines are designed for easy maintenance, and regular inspections can be completed in a short time, ensuring that your equipment always operates at optimal performance.

How to get after-sales support for deburring machines?

We provide 24/7 customer support services. You can contact our technical support team by phone or email at any time, and they will provide you with timely assistance.

If you have any other questions, please ask us!

You are encouraged to contact us at any time for more information or a personalized consultation on deburring machines.

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.