Aluminum Alloy Rapid Melting Furnace

Melting Furnace is designed similarly to a centralized aluminum alloy melting furnace, integrating melting, holding, and tapping functions in one hygienic and environmentally friendly unit. This furnace is ideal for melting and maintaining aluminum alloys and can be used alongside die-casting machines or as a small-scale centralized melting furnace for zinc and aluminum alloys.

Melting Furnace Main Features

- Energy Efficient and Eco-Friendly: High efficiency with low pollution levels, compliant with national environmental standards.

- Low Energy Consumption: Gas consumption is ≤703 per ton, resulting in low operating costs.

- High Thermal Efficiency: Achieves thermal efficiency of over 55%.

- Rational Design: The furnace is designed for ease of use with no dead angles, making it easy to clean and remove slag, with a service life of over five years.

- High-Quality Aluminum Liquid: Maintains aluminum liquid temperature within a ±5°C range, significantly improving product yield.

- Automated Operation: Features manual/automatic feeding, automatic melting, temperature control, and holding, requiring no constant supervision for safe and reliable operation.

- Excellent Insulation: The furnace body has good insulation, with low heat loss and an outer wall temperature of around 65°C.

- Low Aluminum Burn Loss: Aluminum alloy burn loss is less than 1.5%.

- Advanced Control System: Uses PLC and PID controllers for advanced, rational design and simple, convenient operation.

- Versatile Fuel Options: Compatible with liquefied petroleum gas (LPG), natural gas, diesel, and heavy oil.

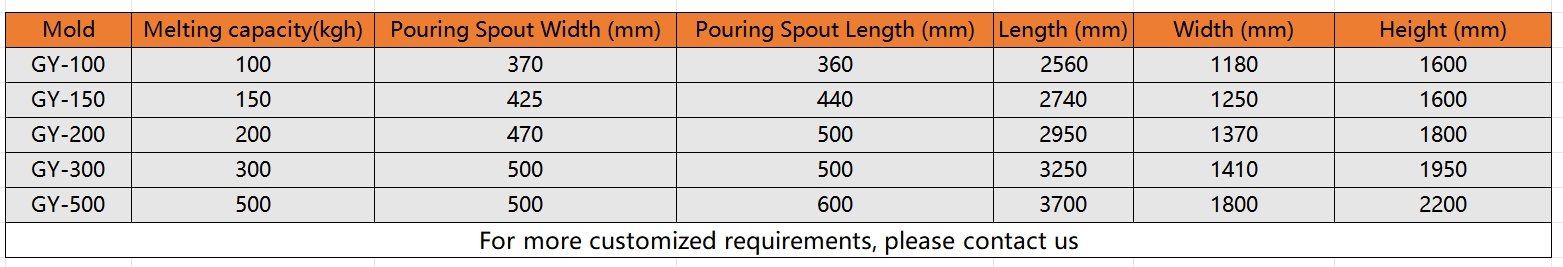

Melting Furnace Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.