Aluminum Alloy Pressure Quantitative Holding Furnace

Holding Furnace is an innovative non-crucible melting furnace designed for the clean, sealed insulation and precise metering of molten aluminum. This furnace features a unique quantitative system that draws aluminum from below the surface of the melt pool, delivering it automatically to die-casting machines or molds with no air exposure, thereby reducing contamination and minimizing oxidation losses.

Holding Furnace Main Features

- Advanced Precision Control: equipped with the latest SUMHONG quantitative control software, this furnace achieves a metering accuracy of ±1.5%.

- Energy-Efficient Insulation: Utilizes high-quality refractory insulation materials from renowned German and American brands, with a sealed design that reduces energy consumption to just one-third of traditional insulation furnaces, cutting down energy costs.

- Minimal Metal Loss: The sealed SUMHONG quantitative furnace features only 0.1% metal loss, representing an approximately 80% reduction compared to traditional insulation furnaces, with temperature deviations kept below ±2°C.

- Safety and Compliance: Designed and manufactured according to European machinery safety standards, using international brand components and Siemens control systems. It includes dual safety protection, safety interlock mechanisms, and emergency stop devices to ensure reliable operation and comprehensive safety for operators.

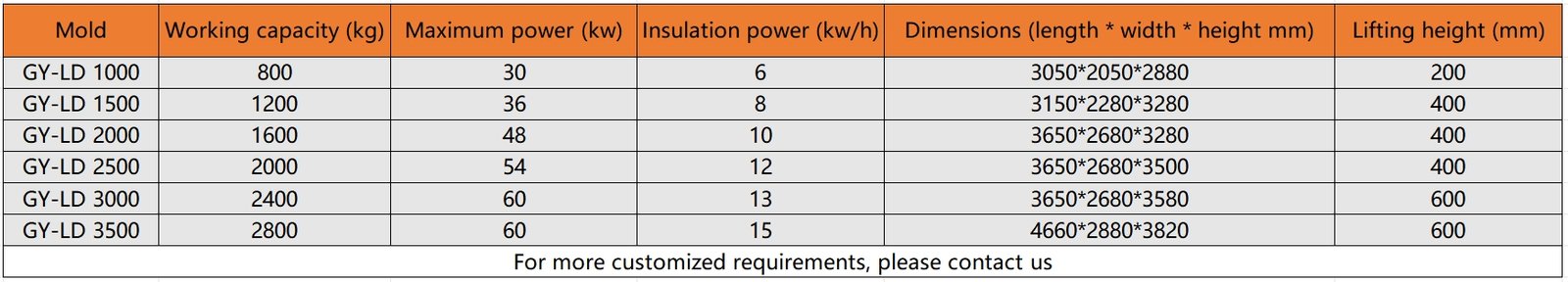

Holding Furnace Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.