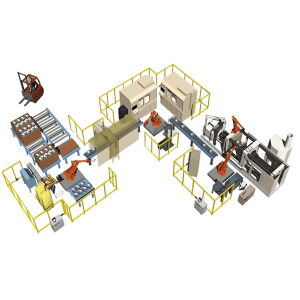

Automatic Soup Distribution Line

The Automatic Soup Distribution Line efficiently manages the distribution of molten metal in die casting processes, ensuring consistent flow and precise control for improved casting quality and reduced waste.

Automatic Soup Distribution Line Key benefits

Efficient Soup Distribution

- Each set of the Automatic Soup Distribution Line can supply 6-16 die casting machines with melting soup.

Fully Automated Operation

After initial setup, it runs continuously without dedicated personnel, optimizing production efficiency.

Real-time process optimization

The system intelligently monitors soup demand from multiple die casting machines, automatically adjusting distribution to minimize downtime and ensure continuous, efficient operation.

Get More

Get more die casting automation solutions, please contact us to improve your production line

Aluminum Alloy Automatic Soup Distribution Line

Automatic Soup Distribution Line is specially designed for soup dispensing in aluminum alloy pressing workshop. It occupies less space and operates automatically in the process of soup dispensing. It is controlled by man machine interface. It is safe, stable and efficient. It can save a lot of production costs for enterprises. The soup dispenser can take large amount of soup at one time, which can satisfy the needs of the melting soup machine in the workshop.

Automatic Soup Distribution Line Main Features

Durable Construction:

- Crafted from high-quality heat-resistant steel with a baked finish, ensuring reliable performance under continuous high temperatures.

Premium Electrical Components:

- Utilizes top international brands for low failure rates and exceptional performance.

Advanced Safety Design:

- Equipped with multiple safety devices to ensure safe operation at high temperatures.

User-Friendly Interface:

- Features a man-machine interface and LED display for straightforward control and clear monitoring of the running status.

Innovative Soup Spoon Material:

- Made from imported composite fiber ceramics integrated with a heat-resistant steel core. High strength and non-stick properties maintain aluminum quality.

Versatile Energy Sources:

- Compatible with oil, natural gas, and biomass for flexible energy use.

Cost-Effective Solutions:

- Custom-designed planning to minimize customer operating costs.

Tiltable Zinc Alloy Automatic Soup Distribution Line

Main Features

Core Components:

- Our Tiltable Zinc Alloy Automatic Soup Distribution Line features core components imported from reputable brands in the United States and Japan, ensuring stable performance and a very low failure rate.

Comprehensive Functionality:

- Contains all the functions of a traditional vertical soup distribution line, offering enhanced versatility and efficiency.

Efficient Design:

- Eliminates the need for diversion troughs and reduces replacement costs by pouring the soup directly into the crucible, minimizing heat loss and optimizing energy usage.

User-Friendly:

- Once initially debugged, workshop managers can easily manage and control the equipment, requiring no specialized supervision for ongoing operation.

Safety Systems:

- Equipped with multi-channel safety alarms and signal detection devices, ensuring stable and safe operation throughout its use.

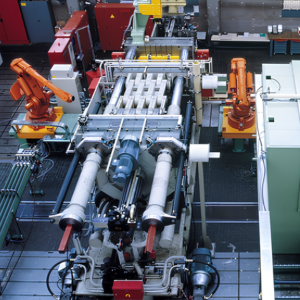

Vertical Zinc Alloy Automatic Soup Distribution Line

Main Features

Fully Automated Operation:

- The Vertical Zinc Alloy Automatic Soup Distribution Line operates fully automatically once the initial programming is set up. It requires no dedicated personnel during use, ensuring 24-hour uninterrupted operation as long as the central melting furnace is sufficiently supplied with soup.

Efficient Soup Distribution:

- Each set of the Automatic Soup Distribution Line can supply 6-16 die casting machines with melting soup, and its fast dispensing speed ensures extremely high efficiency.

Cost-Effective:

- By utilizing centralized soup distribution, the machine furnaces only need to maintain temperature, saving significant melting material costs. There is no need for continuous manual feeding and slag removal, greatly reducing production costs.

Safety Features:

- The mechanical parts are made with high-quality imported components. The soup distribution main machine is equipped with an LED signal display for intuitive monitoring of its status. The electric control cabinet features a large touch screen for easy human-machine interaction, simplifying parameter testing and equipment recording.

Efficient Allocation:

- The soup distribution machine takes soup from the central furnace and allocates it to multiple die casting machines based on soup demand signals. Any remaining soup automatically returns to the central furnace crucible, ensuring safety and saving distribution time.

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.