Fuel (gas) Melting Furnace (gas metal melting furnace)

Gas metal melting furnace features an oval or circular design and is primarily used for melting and maintaining aluminum alloys. It is typically employed as a side furnace for die casting machines but can also serve as a small-scale zinc alloy melting or slag recovery furnace. The oval-shaped furnace can be equipped with a smoke exhaust hood to efficiently remove fumes, ensuring a clean and environmentally friendly operation. The round furnace can be customized with cast iron or graphite crucibles based on customer requirements.

Main Features

- Durable Construction: The furnace body is built with multi-layer, high-quality refractory materials that withstand flame impact and high temperatures.

- Superior Insulation: Equipped with a composite lining made from premium thermal insulation materials for rapid heating and excellent heat retention.

- Efficient Fuel Burning: Features an imported fuel burner that ensures complete combustion, high thermal efficiency, and fast melting speeds.

- Precise Temperature Control: Uses a thermocouple to measure temperature directly in molten aluminum, providing accurate temperature control and reducing scrap rates.

- Automatic Fuel Regulation: The electronic control system adjusts the burner operation based on aluminum temperature, optimizing fuel efficiency.

- Minimal Temperature Fluctuation: The oval-shaped furnace minimizes temperature impact when adding cold materials, ensuring consistent production.

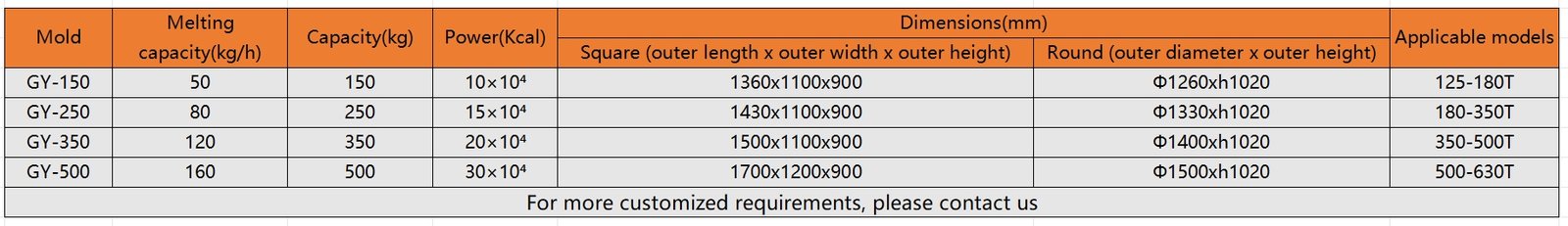

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.