Crucible-less Electric Holding Furnace (Reverberatory Furnace)

Reverberatory Furnace utilizes high-quality imported refractory non-stick aluminum casting materials and high-density thermal insulation boards. This design minimizes surface heat loss, ensuring excellent insulation with a surface temperature of approximately 40°C. The furnace maintains stable aluminum temperatures, offers ease of use, is environmentally friendly, and cost-effective. Heating options include top radiant and bottom immersion heating.

Reverberatory Furnace Main Features

- Electric Heating: Electric Holding Furnace Uses electricity as the heating source for an eco-friendly and hygienic operation, improving the working environment.

- Premium Refractory Lining: The furnace chamber features high-quality non-stick aluminum casting materials that prevent iron contamination and ensure aluminum quality.

- Advanced Insulation: Equipped with composite lining made from high-quality thermal insulation materials, allowing for rapid heating and superior insulation.

- Precise Temperature Control: Employs thermocouples for direct temperature measurement in molten aluminum, ensuring accurate control and reducing scrap rates.

- Efficient Power Management: The PID control system automatically adjusts power output to maximize energy savings.

- Convenient Furnace Lid: Features a cylinder-operated lid design for easy and timely removal of aluminum dross and oxides.

- Energy-Efficient Heating: Uses high-quality silicon-carbide heating rods that are energy-efficient and easy to replace.

- Crucible-Free Design: Eliminates the cost of crucibles, reducing overall expenses.

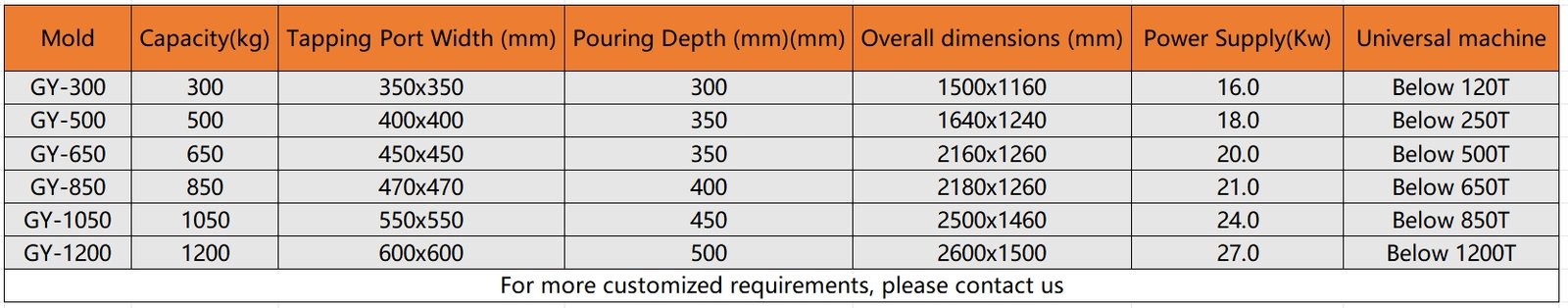

Reverberatory Furnace Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.