Die Casting Sprayer

SUMHONG Die Casting Sprayer offers high-performance atomization, precise mold cleaning, and flexible spray adjustments for smooth, efficient casting operations.

Key benefits

Faster cycle times

The Die Casting Spray features advanced multi-circuit spraying technology, ensuring faster cycle times and greater efficiency in your production line.

User-friendly controls

Control the sprayer directly from your die-casting machine’s display unit for a smooth, hassle-free operation and faster die changes.

Real-time process optimization

Real-time data integration ensures that the die casting spray works seamlessly with the rest of your equipment for smoother operations and better process management.

Get more die casting automation solutions, please contact us to improve your production line

Single arm servo wolin sprayer

Main Features

Durability and Stability

- Multi-Link Structure: The SUMHONG Die Casting Machine Sprayer features a robust multi-link design, ensuring high mechanical strength, stability, and a long service life.

- Single-Arm Servo Copper Tube: The sprayer uses a high-quality copper tube in a single-arm configuration, providing improved durability and consistent performance.

High-Performance Components

- Advanced Motor and Reducer: Equipped with a premium brand reducer, motor, and Japanese NSK bearings, ensuring reliable and efficient operation.

- Inverter and Servo Control: The Single-Arm Servo Wolin Sprayer is powered by a high-performance inverter and servo control, delivering precise and smooth operation for optimal spray results.

Versatile Operation

- Flexible Use: The sprayer can operate independently or be integrated with die casting machines, soup machines, or take-out machines, creating a fully automated production system.

- Optional Nozzles: Choose between a brass nozzle or an independent atomizing nozzle for superior spray performance, tailored to your production needs.

Time-Saving Features

- Pre-Shutdown Function: The Die Casting Spray System includes a pre-shutdown function, effectively reducing spraying time and improving efficiency.

- Electric Mode Thickness Adjustment: The electric mode allows for precise adjustment of spray thickness, providing flexibility to meet varying product specifications.

Self-Diagnosis and Maintenance

- Fault Self-Diagnosis Display: The SUMHONG Die Casting Machine Sprayer includes a self-diagnosis feature, displaying fault codes to facilitate quick troubleshooting and maintenance, ensuring minimal downtime.

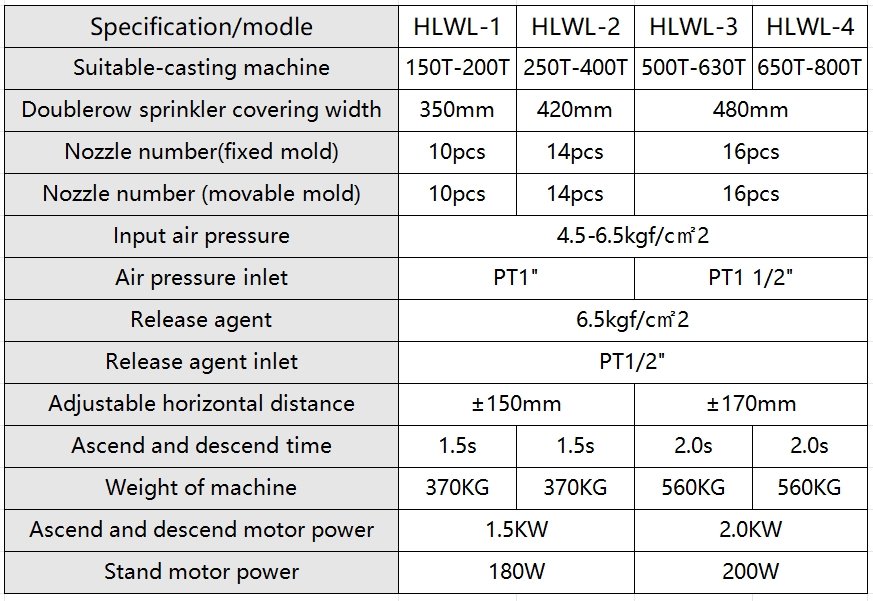

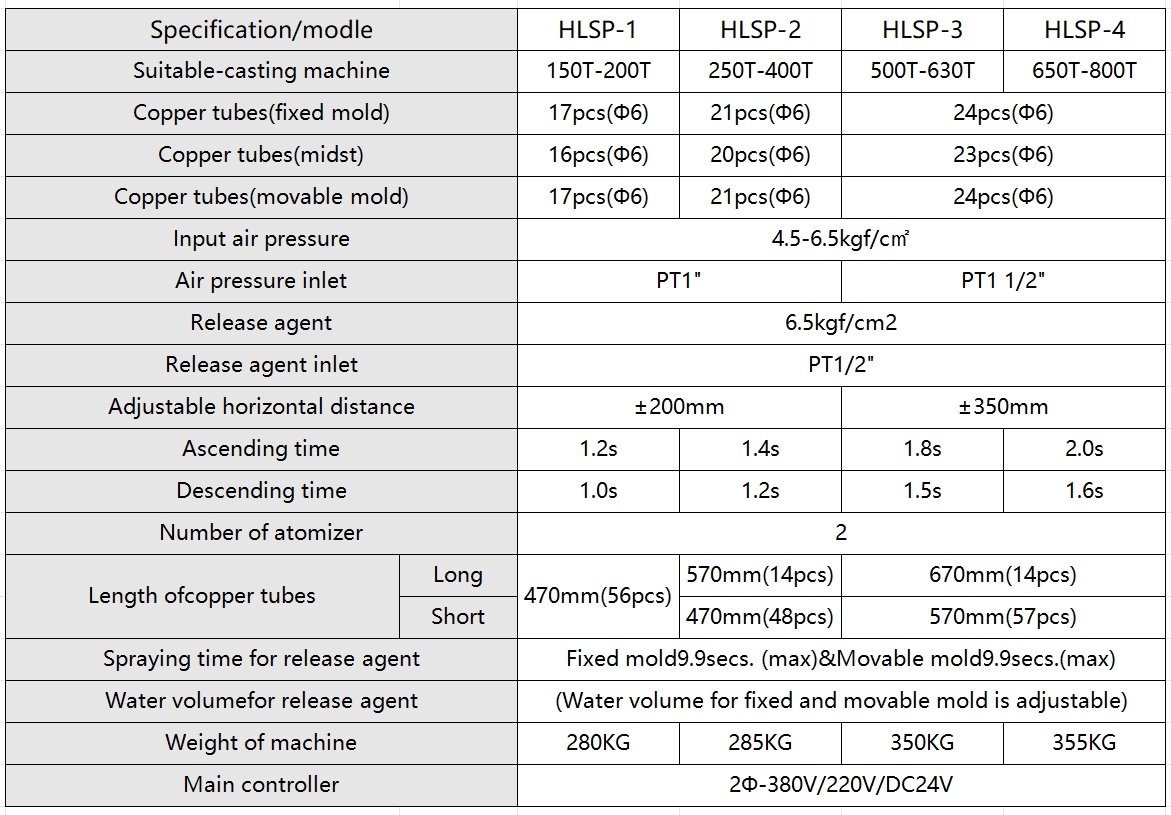

Equipment parameters

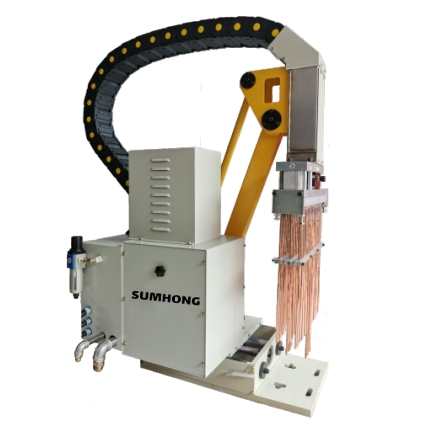

Single arm servo copper tube sprayer

Main Features

Sturdy and Reliable Design

- Robust Construction: The SUMHONG Die Casting Machine Sprayer is designed with a high-strength multi-link structure, ensuring excellent stability and long-lasting performance.

- Single-Arm Servo Copper Tube: The sprayer’s single-arm servo copper tube offers superior durability and stable operation over extended periods.

High-Efficiency Operation

- Reliable Motor and Reducer: Features a high-quality brand reducer, motor, and Japanese NSK bearings for smooth, efficient operation and lower risk of failure.

- Servo Control Precision: The Single-Arm Servo Wolin Sprayer integrates a high-performance inverter and servo system for precise control of spray patterns.

Versatile and Automated Use

- Independent or Integrated Use: Operate the sprayer as a standalone unit or connect it with die casting machines, soup machines, or take-out machines to form a fully automated production system.

- Choice of Nozzles: Offers an optional brass nozzle or independent atomizing nozzle, allowing you to select the best spray solution for your specific needs.

Enhanced Time and Efficiency

- Automatic Pre-Shutdown: The sprayer features an advanced pre-shutdown function, significantly reducing spray time for faster production cycles.

- Adjustable Spray Thickness: The electric mode for thickness adjustment ensures spray consistency, accommodating a wide range of casting requirements.

Easy Maintenance and Diagnostics

- Self-Diagnosis Display: The sprayer includes a fault self-diagnosis feature, making maintenance easier and ensuring quick identification of potential issues.

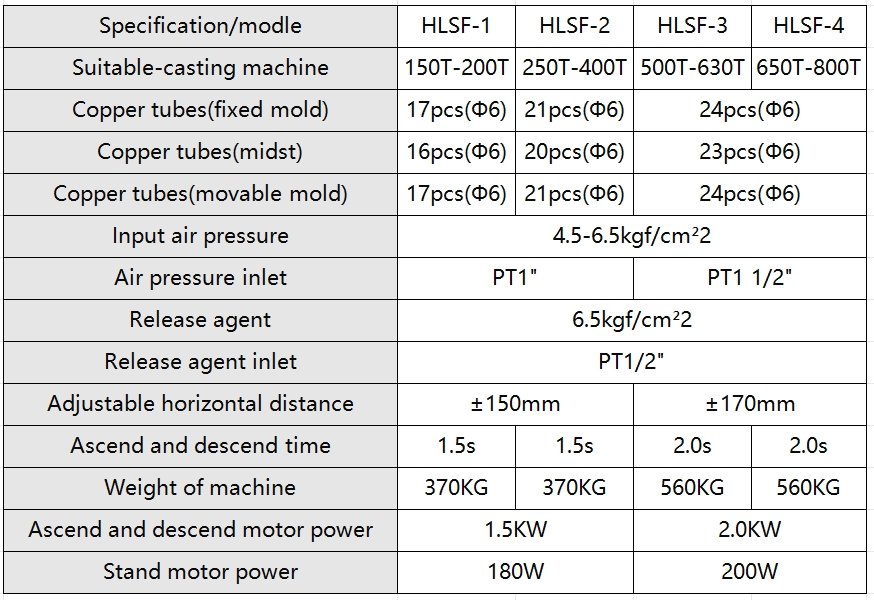

Equipment parameters

Single arm servo wolin sprayer

Main Features

Improved Production Efficiency

- Upright Positioning: The sprayer can be set to an upright position before or after the designated function, optimizing production flow and improving overall efficiency.

- Durable Structure: The mechanical design is simple yet highly durable, ensuring long-lasting, reliable performance in demanding production environments.

Advanced Control and Maintenance

- PLC Control System: Features a PLC control circuit that simplifies operation and provides real-time diagnostics.

- Fault Code Display: Built-in fault code display for quick troubleshooting, enhancing maintenance efficiency and minimizing downtime.

Superior Atomization Performance

- Dual Nozzle System: Equipped with two or more atomizer nozzles, delivering enhanced atomization for better spray coverage.

- Adjustable Mold Settings: Fixed and movable molds can adjust the water flow size with no leakage, allowing for precise spraying of thin castings and maximizing atomization efficiency.

Flexible Operation

- Independent or Automated Operation: Can function as a standalone unit or be integrated into an automated production line with die casting machines, spray machines, or take-out machines for fully automated processes.

Efficient Mold Cleaning

- Blow Function: The sprayer’s blow function can be raised to clean both the fixed and movable mold surfaces after spraying, ensuring the molds are thoroughly cleaned and ready for the next cycle.

Precise Spray Control

- Adjustable Release Agent Spraying: The sprayer allows precise adjustment of release agent quantities and can independently control the spray times for both the fixed and active sides of the mold, offering customization for different product types.

Stable and Safe Movement

- Smooth Speed Control: The up-and-down movement speed is stable, with a rapid deceleration feature that prolongs the actuator’s life. The speed is adjustable, ensuring optimal operation.

- Fall Prevention Device: A built-in fall prevention device protects the nozzle when the air source is closed, preventing damage.

Customizable Options

- Tailored Spray Devices: The sprayer is highly customizable to meet specific customer needs, and the standard nozzle can be replaced with specialized modules for different spraying requirements.

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.