Automatic Deburring Machine-SYNTEC

Our automatic deburring machine offers cost-effective automation, making it the ideal choice for manufacturers looking to streamline deburring and optimize production costs. Here’s what makes it stand out:

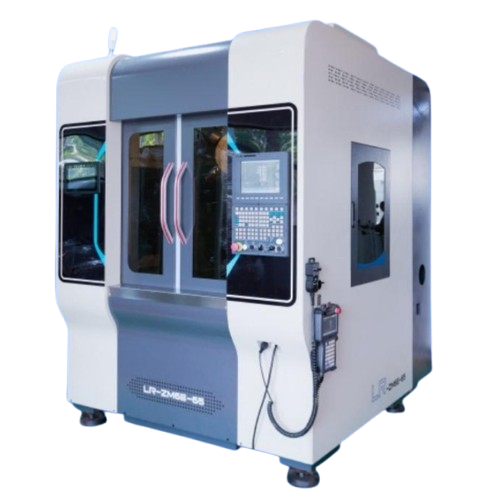

High-Speed Multi-Axis Control

Featuring the SYNTEC multi-axis control system and servo motor, this system provides fast, responsive performance, enabling efficient deburring and grinding for complex geometries. The extensive program storage capacity allows quick access to stored configurations, minimizing downtime and reducing repetitive programming requirements.

Enhanced Structural Integrity

Constructed using cast iron mold-forming technology, the machine offers exceptional rigidity and stability, a critical feature for minimizing tool vibration. This ensures faster feed speeds and optimizes the deburring process for high-quality outcomes on various metal parts.

Precision Six-Axis Movement

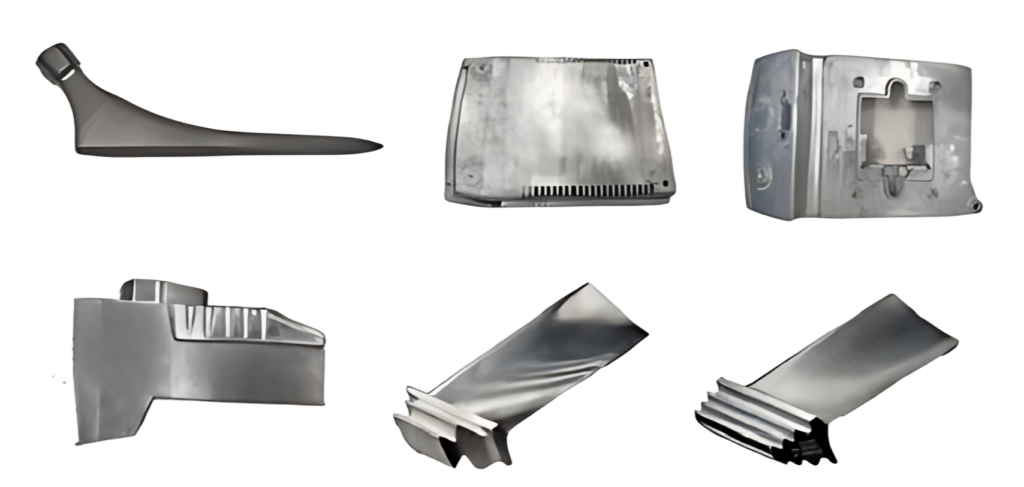

The six-axis grinding capability allows intricate, multi-directional grinding with seamless movement along the X, Y, and Z axes, as well as rotational control over the A, B, and C axes. This flexibility enables comprehensive deburring and grinding processes for diverse production demands.

Efficient accurate reliable

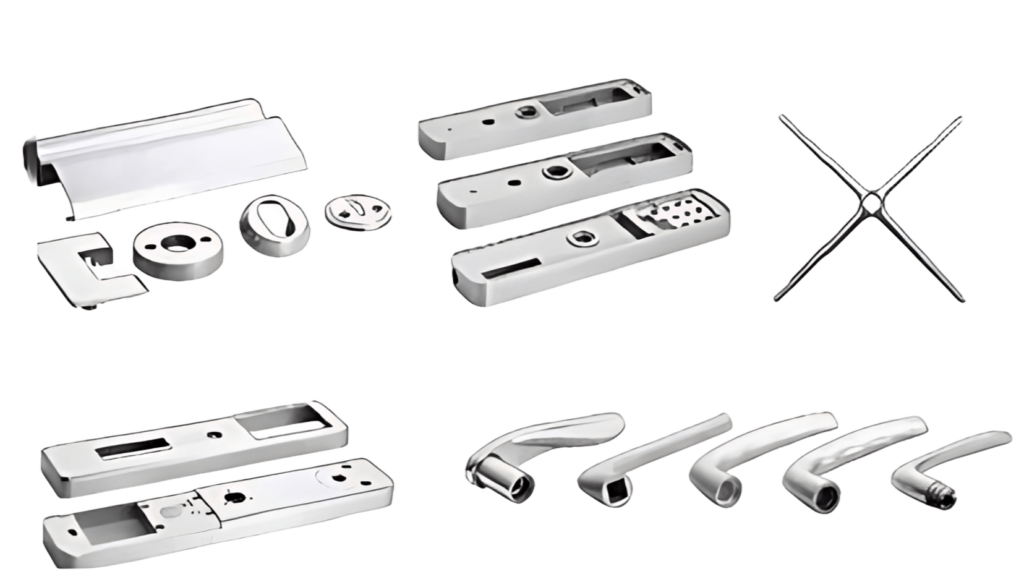

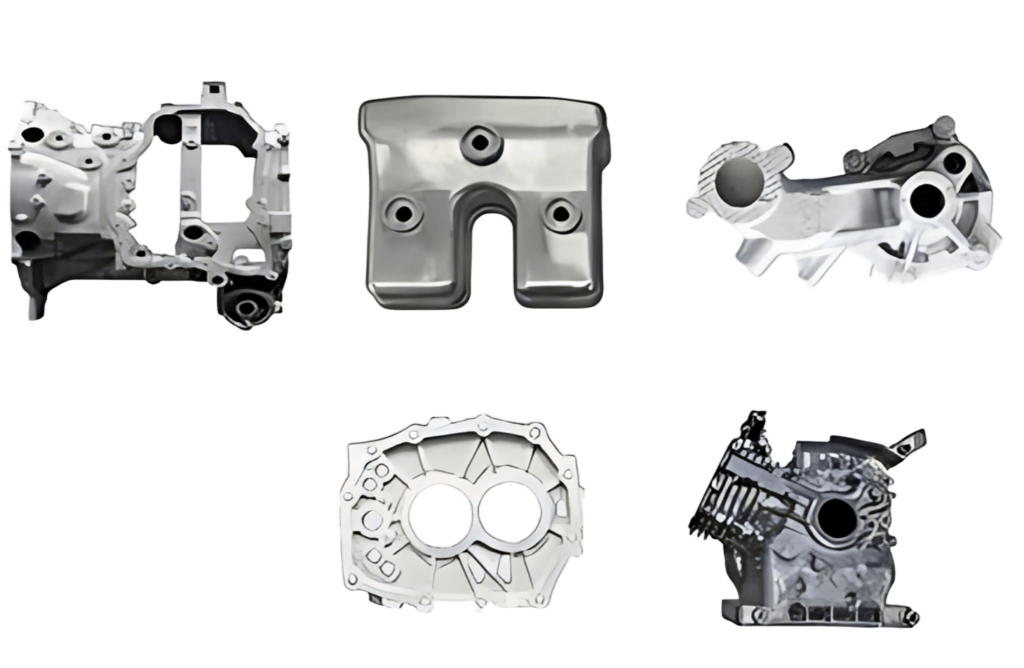

We provide automatic deburring machine solutions to solve core problems across multiple industries.

Incoming Consistency

Through the floating forcecontrol and visual inspectionsystem, the problem of poorconsistency of incomingmaterials is solved and theyield is guaranteed.

Finished Quality

Through the closed-loopcontrol system and detectiontechnology, the quality controlof the finished products ofhigh-precisionproducts;isrealized.

Tools & Consumables

SUMHONG has built a powerfulprocess library and customizedrobot grinding consumablessuitable for its product processfor customers.

Offline Programming

Through off-line programming technology,rapid productproductswitching and newcopyingprocedurescan berealized

Automatic Deburring Machine-SYNTEC

Performance Advantages

High-Precision Metal Deburring Machine for Die-Casting Operations with Multi-Axis Control

Single-Clamp, Multi-Angle Processing

Thanks to the six-axis setup, our equipment allows single-clamp positioning, enabling multi-angle processing and ensuring that sharp edges are smoothly deburred across all angles without repositioning. This not only speeds up processing but also enhances precision and consistency, producing high-quality parts in fewer steps.

Versatile Tool System

The six-head rotary tool magazine, combined with quick tool change features, ensures seamless tool changes without fixed positions, making it adaptable for both flexible and rigid tooling. The equipment’s tool compatibility extends its capabilities, supporting the precise requirements of various deburring and grinding tasks.

Automated Tool Compensation

Designed to maximize tool life and reduce wear, the automatic tool compensation feature maintains optimal performance throughout the deburring process, reducing downtime and supporting continuous, cost-effective production.

- Precision flexible control system

- Parameterized closed-loop control system

- Abrasive and position compensation system

- Automatic Dimension and Displacement Detection System

- Automatic tool and consumable change system

- Automatic Tool Library System

- Standard Consumables Process Database

- Automatic chip removal systems

- Dust and sound proofing safety systems

- learn more

Equipment parameters

See What Our Customers Ask Frequently

We provide detailed answers to some questions you may have

What materials are our deburring machines suitable for?

Our deburring machines can efficiently process a wide range of materials, including metals, plastics and composites, ensuring they meet the needs of a wide range of industries.

How long does it take to maintain a deburring machine?

Our deburring machines are designed for easy maintenance, and regular inspections can be completed in a short time, ensuring that your equipment always operates at optimal performance.

How to get after-sales support for deburring machines?

We provide 24/7 customer support services. You can contact our technical support team by phone or email at any time, and they will provide you with timely assistance.

If you have any other questions, please ask us!

You are encouraged to contact us at any time for more information or a personalized consultation on deburring machines.

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.