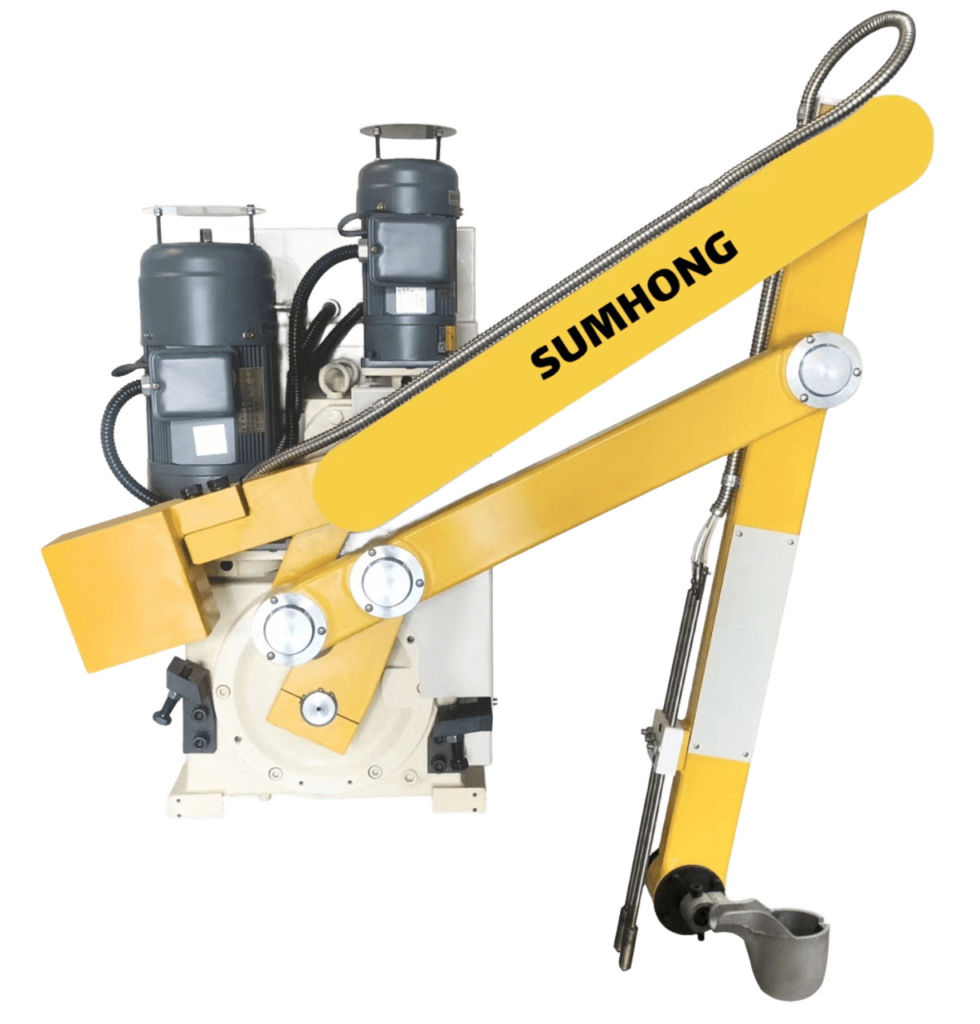

Automatic Ladle Machine

SUMHONG Automatic Ladle Machine ensures smooth, high-speed operation, flexible control, and easy maintenance with fault self-diagnosis and integration into automated casting processes.

Automatic Ladle Machine Main Features

Enhanced Stability and Speed:

- Equipped with a five-link structure, the arm delivers stable high-speed motion, ensuring smooth braking and preventing aluminum melt overflow.

Reliable and Durable:

- High-performance reducer ensures stable, reliable performance for long-lasting operation, even under demanding conditions.

Precise Motion Control:

- The arm’s forward and backward movement is controlled by a frequency inverter, allowing for faster metal pouring and more efficient operation.

User-Friendly PLC Control:

- Features PLC control with a touch panel for easy function selection, and built-in fault code display for quick troubleshooting and easier maintenance.

Flexible Operation Modes:

- Can operate in manual or automatic mode, allowing for flexibility in operation based on production needs.

Integration with Die-Casting Systems:

- Can be integrated with die casting machines, spray machines, and take-out machines, forming a complete automated production line.

Self-Diagnosis:

- Equipped with a fault self-diagnosis display for faster detection of any issues, reducing downtime and simplifying maintenance.

Automatic Ladle Machine Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.