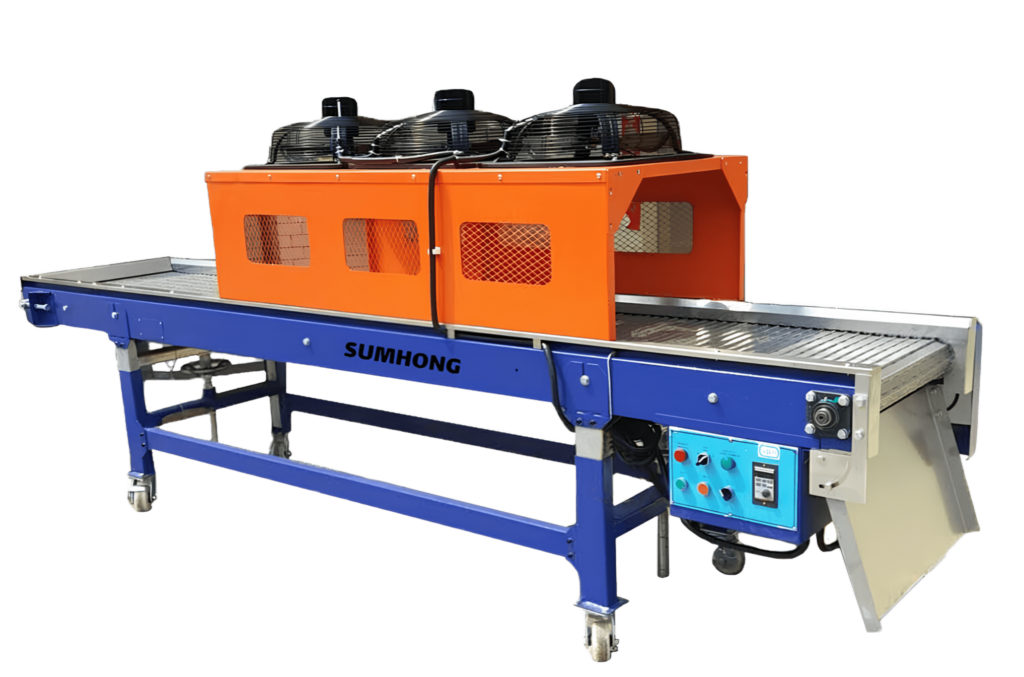

Cooling Conveyor

The Cooling Conveyor efficiently cools metal parts in die casting, ensuring uniform temperature distribution and preventing distortion. It integrates easily into automated lines, reducing cycle times and enhancing part quality. Durable and energy-efficient, it’s ideal for high-volume die-casting and manufacturing applications.

Cooling Conveyor Main Features

Optimized Production Efficiency:

- Enhances die-casting line performance by streamlining the cooling process, improving overall productivity, and minimizing delays. The system features adjustable transmission speeds to match product volumes, ensuring efficient processing.

Fog Elimination System:

- Effectively removes fog during the cooling phase, ensuring clear visibility and precise handling of die-cast parts, critical for quality control. Cooling fans can be added based on product size and requirements to accelerate cooling.

Accelerated Cooling Process:

- Reduces cooling time for hot die-castings, enabling faster cycle times and boosting throughput. Adjustable cooling fans enhance the process, speeding up production cycles.

Tailored System Configuration:

- Offers flexible configuration with adjustable components, ensuring seamless integration into your die-casting system. The height can be adjusted, and it can link with other machines for fully automated operation.

Adaptable Dimensions:

- Customizable length, width, and height to accommodate various die-casting molds. The conveyor is made of durable stainless steel and carbon steel chain plates, with specifications tailored to your needs.

Overhead Cooling Mechanism:

- Uses overhead fans for efficient cooling and drying, ensuring precise temperature control. Variable frequency control stabilizes operations, allowing smooth adjustments for cooling demand.

Workplace Safety Enhancement:

- Improves safety by reducing operator exposure to heat and handling risks, and by offering flexible work cycles with timer control for intermittent or continuous operation, minimizing safety hazards.

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.