DCC-Series Cold Chamber Die Casting Machine

User-Friendly

Easy-to-use interactive system

High-Performance

Up to 40% with innovative hydraulic.

Advanced Technology

Intelligent real-time control system

Durable & Reliable

Long-lasting Operational Lifespan

SUMHONG Cold Chamber Die Casting Machine for die cast aluminum and alloys

Die cast aluminum and its alloys are essential materials in sectors like automotive, aerospace, and electronics. Known for their durability and lightweight properties, die cast aluminum material ensures high performance. SUMHONG Cold chamber die casting machines are specifically designed to handle the high pressure needed to process aluminum and alloys, making them ideal for producing intricate and reliable components.

Cold Chamber Die Casting Performance Advantages

Advanced Operating System

– Color touch screen provides clear operation instructions and powerful operating functions

– Advanced intelligent control system with more features for easier use (optional)

Intelligent Mold Adjustment System

– Gear mold adjustment with brake ensures precise positioning without displacement, resulting in more stable production

– Intelligent mold adjustment system saves complex operations (optional)

Stable Injection Unit

– Coaxial core design provides strong and stable injection force

– Hydraulic check valve configuration allows for faster and easier pressure boost control

– Hammer position uses a non-contact magnetic encoder, making it more convenient and durable

– Electric or intelligent injection control provides more advanced injection control functions (optional)

Clamping System

– Unique toggle mechanism and tie-bar design for durability and reliability

– Mold opening back pressure oil circuit design for faster and more stable mold opening and clamping

Energy Efficiency & Safety Door

– Low energy consumption design for high efficiency and energy savings

– Servo energy-saving system for significantly reduced energy consumption (optional)

– Lightweight design reduces labor intensity

– Electric door for fully automated operation (optional)

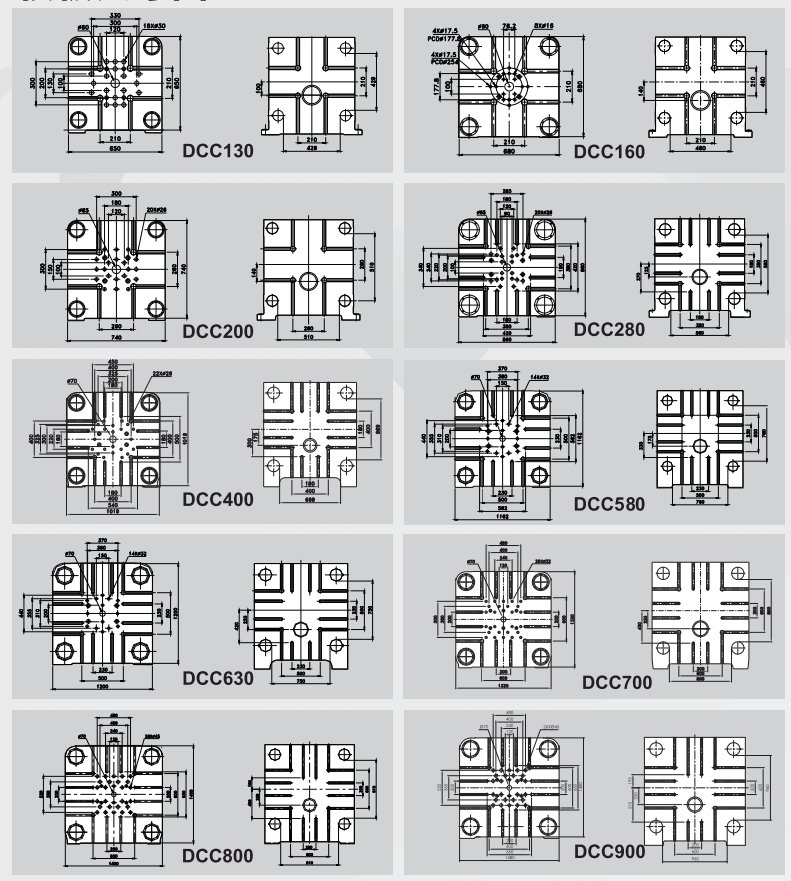

Mold Platen Layout

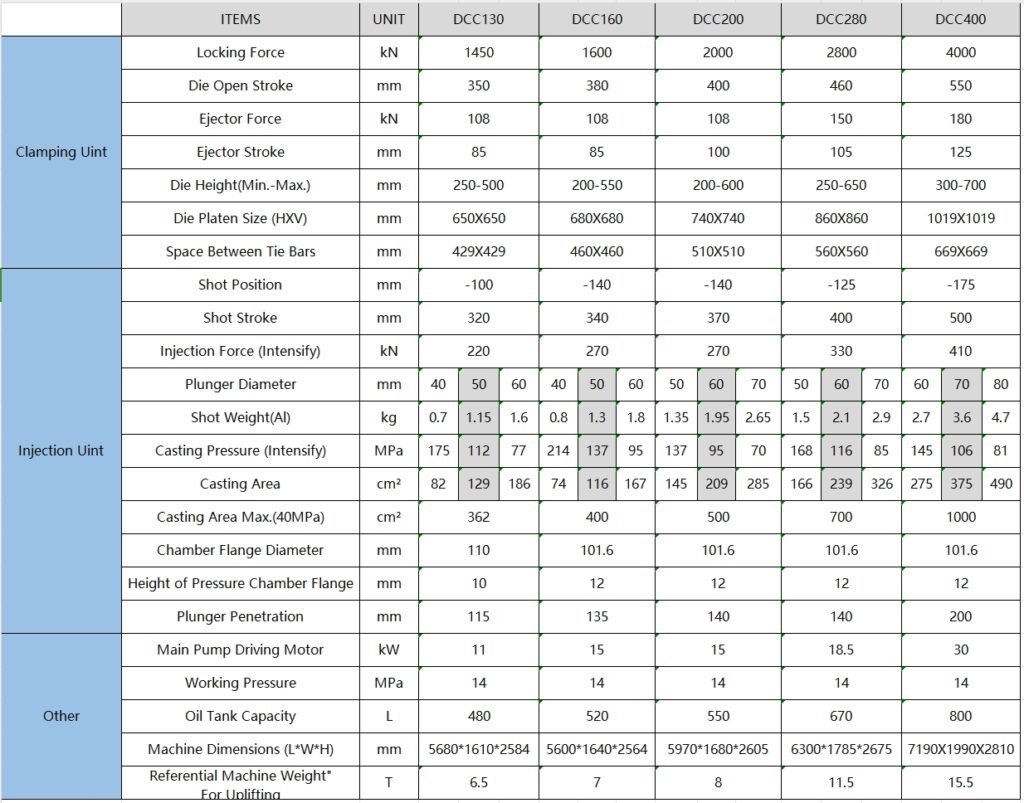

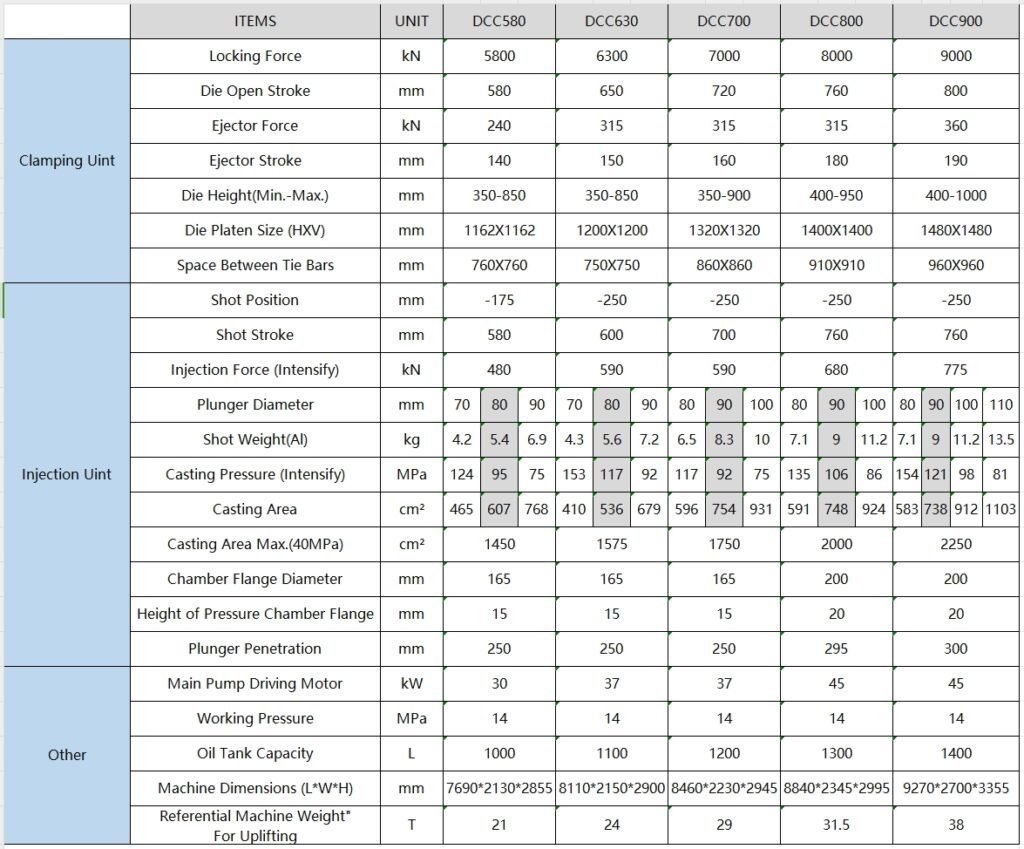

Specification

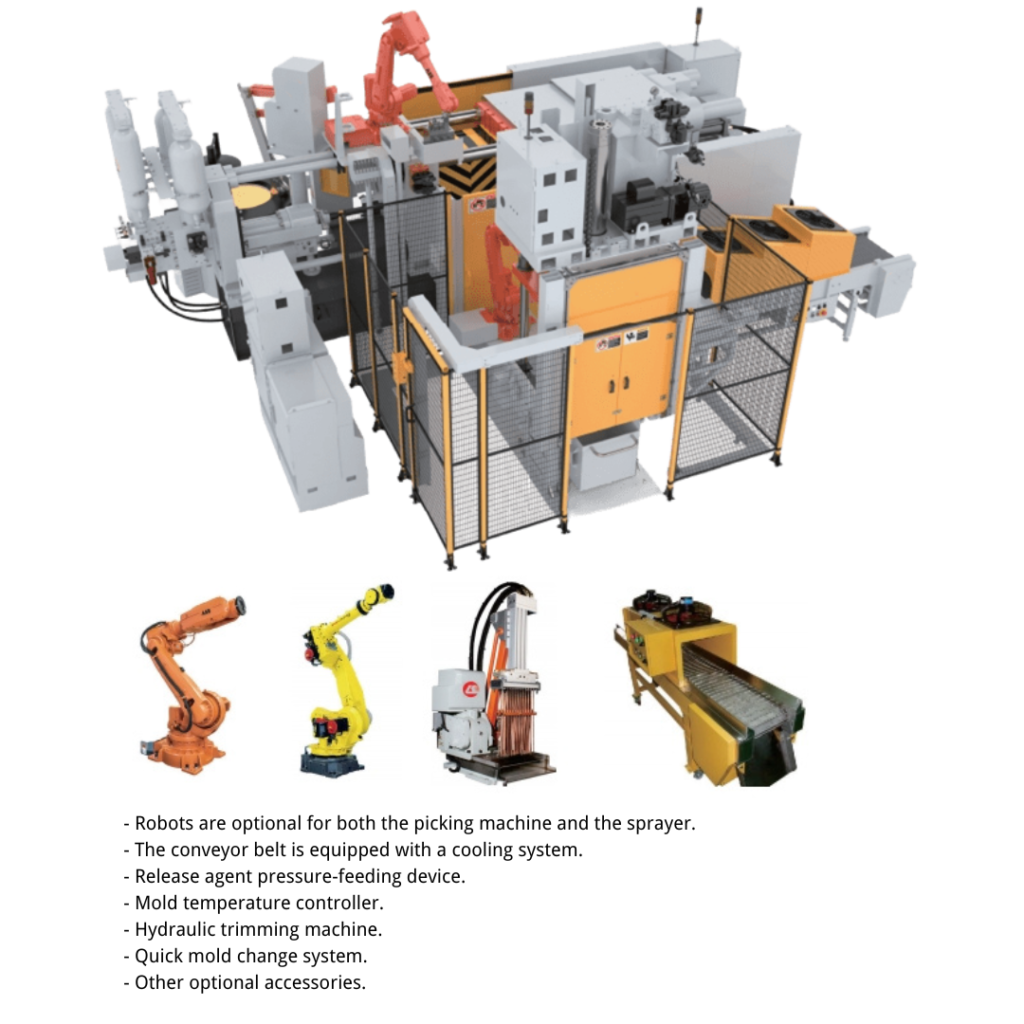

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.