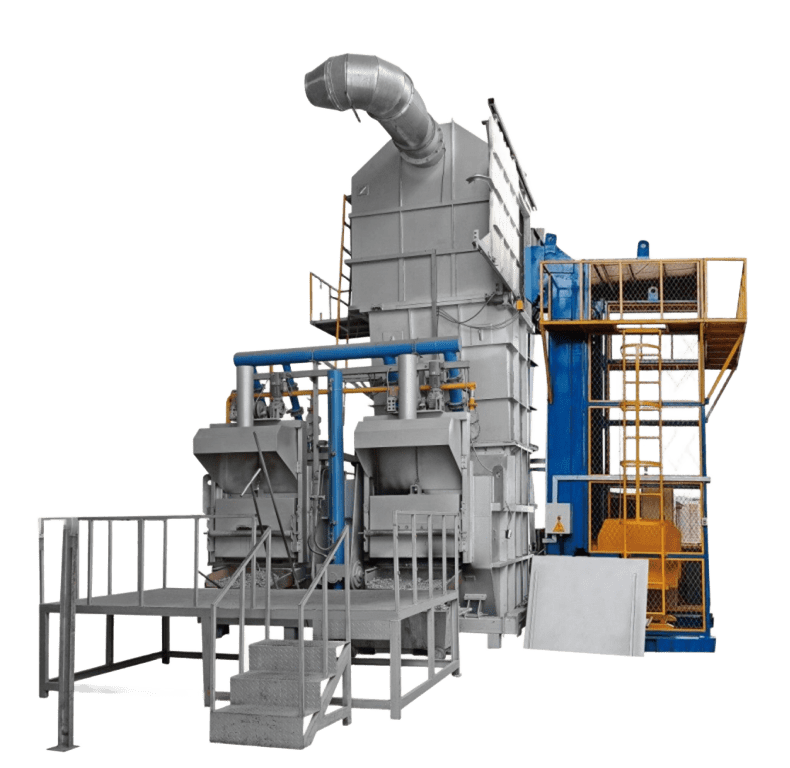

Aluminum Alloy Continuous Melting Furnace (Central Furnace)

Central Furnace is designed for the rapid and efficient melting of aluminum alloys, ideal for large-scale aluminum die-casting and casting operations. This furnace offers exceptional energy efficiency, low metal loss, and automated operation.

Central Furnace Main Features

- Durable Construction: Built with high-quality imported refractory materials and an integrated furnace lining, providing a lifespan of over five years.

- Versatile Fuel Options: Compatible with a variety of fuels including liquefied petroleum gas (LPG), natural gas, diesel, and heavy oil.

- High Melting Capacity: Capable of melting 500-3000 kg/h.

- Efficient Melting Process: Utilizes a low-speed infrared long flame burner, ensuring minimal material loss and extremely low oxidation rates. Metal loss does not exceed 1.5%.

- Superior Insulation: Features a special furnace design and high-quality insulation materials that reduce heat dissipation, keeping the furnace surface temperature low. Temperature differences between the melting chamber and the pouring chamber are controlled within ±5°C.

- Automated Operation: Supports manual/automatic feeding, automatic melting, temperature control, and insulation, eliminating the need for constant supervision and ensuring safe, reliable operation.

- Advanced Control System: Equipped with a PLC+PID program controller for precise and efficient control, with a design that is both advanced and user-friendly.

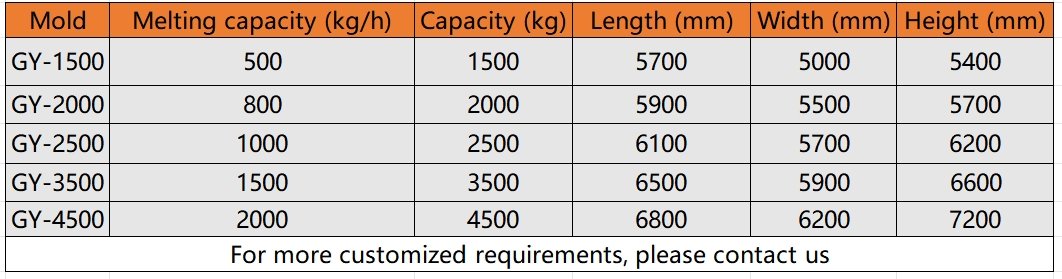

Central Furnace Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.