Degasser For Aluminum Refining(degassing in aluminium casting)

degassing in aluminium casting consists of several key components, including the main frame, motor, graphite rotor, control box, and refining agent tank. The motor drives the graphite rotor to descend and rotate in molten aluminum. Simultaneously, high-purity nitrogen (or argon) and refining agents are introduced to perform degassing, slag removal, and refining. The equipment is available in mobile, stationary, and suspended types, each designed to meet specific operational needs.

Main Features

- Versatile Mobility & Placement: Degasser For Aluminum Refining ,Our degassing device is designed for easy relocation and multiple furnace use. It offers seamless recycling across various locations.

- User-Friendly Controls: Degasser For Aluminum Refining features a simple button operation system. Set degassing times from 0.01 seconds to 999 hours (or infinite), with both automatic and manual control modes. Complete degassing with a single button press, and let the automatic control handle the rest.

- Real-Time Rotor Speed Adjustment: The rotor speed can be adjusted in real time via the inverter, accommodating diverse degassing and refining environments.

- Automated Safety Features: Upon completion of the set degassing time, the rotor stops, air supply closes automatically, and the car cover halts in position for safe operation. The device also includes an alarm system that notifies operators when inert gas pressure drops below the set level.

- High-Efficiency Degassing Medium: Utilizes high-purity nitrogen or argon for superior degassing efficiency. Enhanced refining agent effectiveness ensures optimal results.

- Durable Construction: Equipped with high-temperature-resistant bearings and a motor with air cooling to reduce operating temperature and extend service life.

- Emergency & Maintenance Features: Includes an easy-to-use emergency shutdown button, solid structure, and low maintenance requirements for reliable and straightforward upkeep.

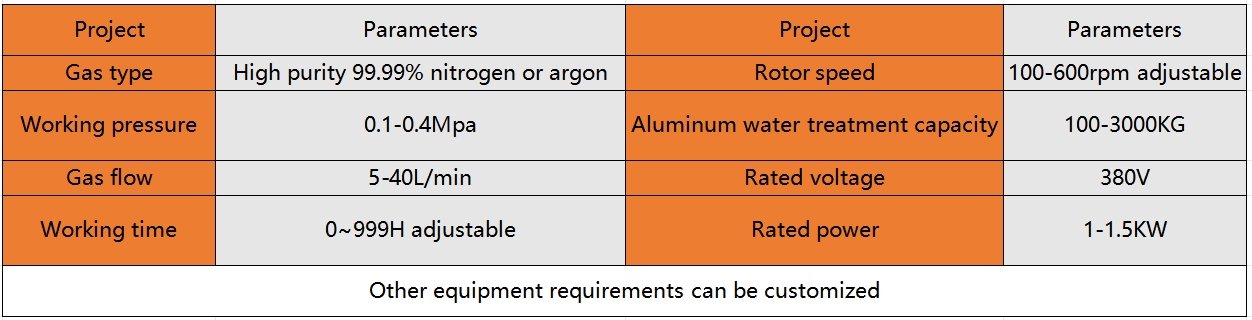

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.