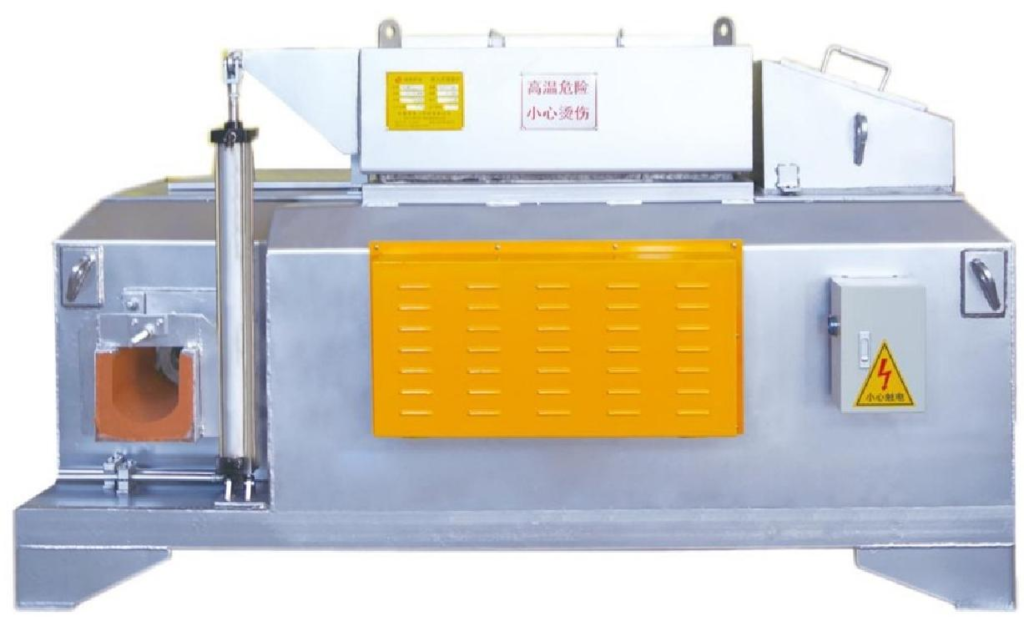

Pour-in Type Electric Holding Furnace

Pour-in Type Electric Holding Furnace is designed for the precise temperature maintenance of aluminum in processes such as metal die casting, gravity casting, or low-pressure casting. It uses ceramic heaters immersed directly in the aluminum to heat the molten metal, offering high thermal efficiency, rapid heating, minimal gas absorption, and uniform temperature distribution.

Electric Holding Furnace Main Features

- High Aluminum Quality: Internal heating reduces gas absorption and oxidation, improving the quality and yield of aluminum.

- Exceptional Heat Efficiency: With all heating elements submerged in the molten aluminum, the immersion heater achieves a heat efficiency of up to 95%, saving over 40% in energy compared to traditional radiant heating furnaces.

- Low Metal Loss: The furnace minimizes metal loss to less than 0.4%, reducing the frequency of furnace cleaning and extending the lining’s lifespan with high-quality refractory materials.

- Safety and Durability: Utilizes imported protective tubes for safe, stable, and long-lasting performance.

- Precise Temperature Control: Equipped with PID temperature control, maintaining accuracy within ±2°C.

- Comprehensive Safety Features: The control box includes multiple safety alarms for aluminum over-temperature, atmosphere over-temperature, and heater disconnection.

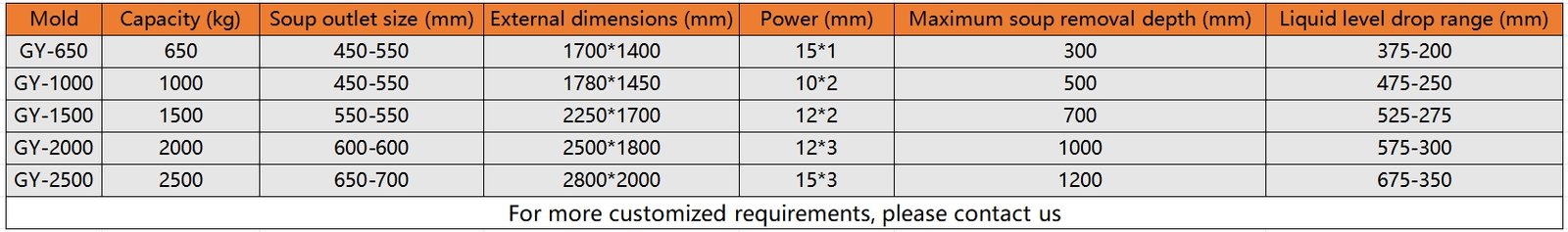

Electric Holding Furnace Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.