Tilting electric metal melting furnace

Tilting electric metal melting furnace is primarily used for melting or refining low-melting-point non-ferrous metals and alloys. The molten metal can be easily poured out, making this furnace ideal for small-scale centralized melting stations.

Main Features

- High-Quality Insulation: electric metal melting furnace,The composite furnace lining is made from premium insulation materials, ensuring minimal heat loss and rapid heating.

- Versatile Heating Options: Can be heated using electricity, oil, or gas.

- Durable Crucibles: Compatible with both imported and domestic graphite crucibles, coated with special materials for extended service life.

- Easy Tilting Mechanism: Options for electric hydraulic or manual worm gear reducers for tilting, providing ease of use.

- Wide Tilting Angle: Furnace body can tilt up to 90 degrees, facilitating the easy pouring of large quantities of molten metal.

- Efficient Temperature Control: PID temperature control system with a silicon-controlled rectifier (SCR) module automatically adjusts power output based on temperature, maximizing energy savings.

- Safety Features: Equipped with a leak-proof safety interlock alarm that can automatically alert and cut off the heating power, ensuring safe operation.

- Optional Insulation Cover: Available as an additional feature to further reduce heat loss and save costs.

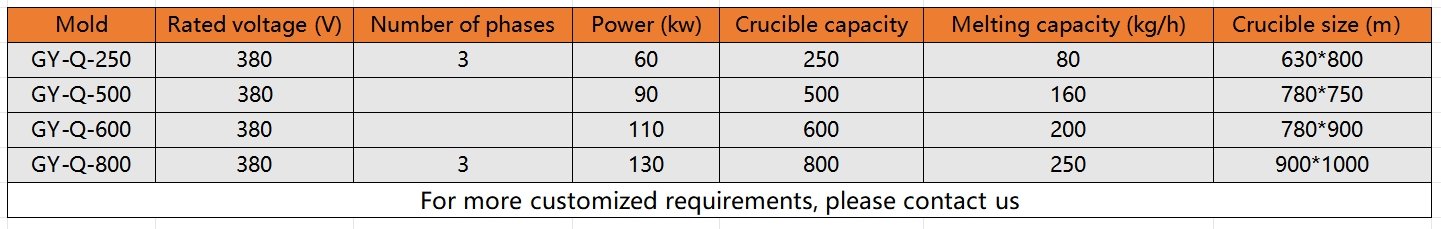

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.