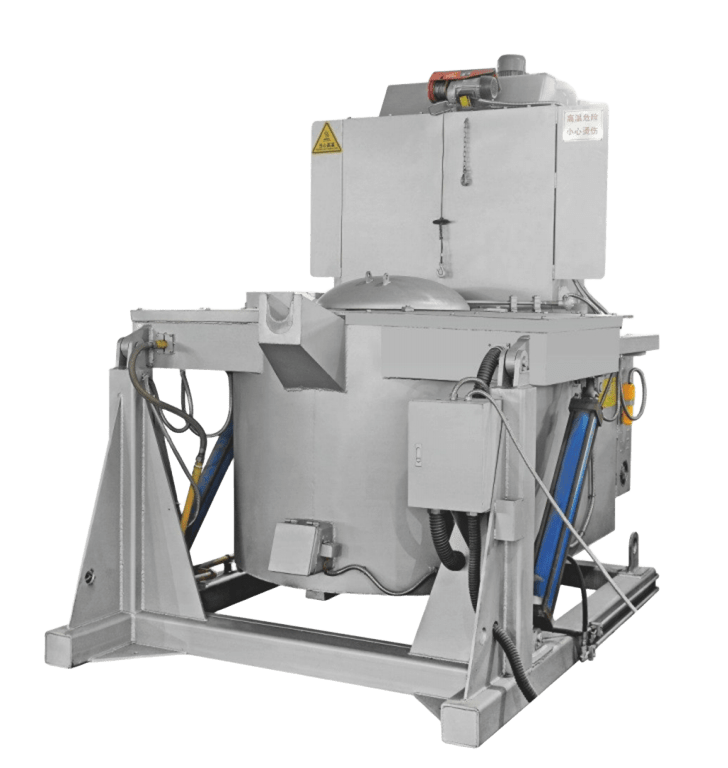

SUMHONG’s Tilting Heat Storage Gas Furnace for melting metal offers a cutting-edge approach to melting zinc, aluminum, and copper. With regenerative technology, it saves over 20% energy compared to electric furnaces and 40% compared to standard gas models.

Main Features

High-Quality Gas Components: Furnace for melting metal ensures stable performance and extremely low failure rates.

Efficient Burner Design: Utilizes regenerative technology, recycling exhaust heat to re-enter the furnace and heat the crucible, resulting in high thermal efficiency and low exhaust gas temperatures.

Superior Insulation: The furnace lining is constructed from high-temperature mullite bricks, ceramic fiber blankets, and nano insulation panels, providing low thermal conductivity and excellent heat preservation, effectively reducing heat loss.

Durable Refractory Materials: The furnace chamber and bottom are made from high-quality refractory castables, offering high resistance to heat and thermal shock, ensuring a long service life.

Dual Temperature Measurement: Features dual temperature measurement for both the material and the furnace chamber, ensuring rapid melting and maximum fuel savings.

Automated Control System: The gas control system automatically adjusts burner power output based on actual temperature, seamlessly switching between melting and holding states.

High-Quality Crucibles: Equipped with high-quality silicon carbide graphite crucibles for excellent thermal conductivity and extended lifespan.

Optional Tilting Mechanism: Available with either electric hydraulic or manual worm gear reducer tilting mechanisms for easy and convenient operation.

Insulating Furnace Cover: Optional insulating furnace cover to reduce heat loss and save costs.

Safety Features: Equipped with a leak detection safety interlock alarm system that can automatically alert and shut off the burner, ensuring safe operation.

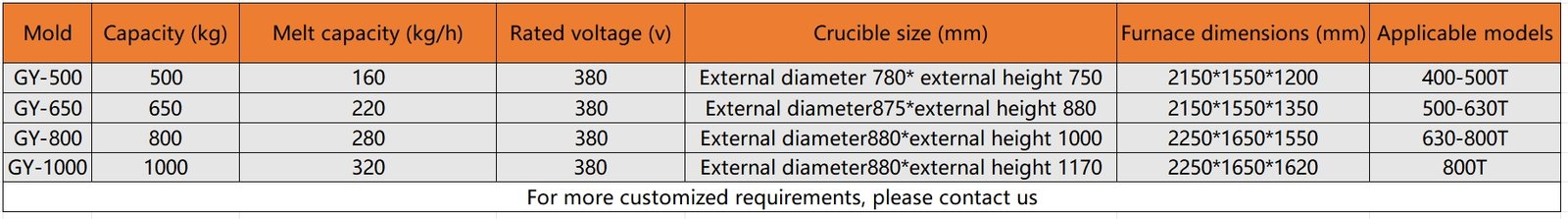

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.