SUMHONG furnace melting for Zinc Alloy is engineered for efficient melting and thermal insulation of zinc alloys, compatible with all mainstream zinc alloy die-casting machines currently available on the market.

Main Features

Electric Heating: Furnace melting Utilizes electricity with imported heating elements, meeting European WEB environmental standards for production equipment.

Energy Efficiency: Approximately 40% more energy-efficient than diesel fuel, offering low operational costs and high thermal efficiency.

Durable Cast Iron Crucible: Comes with a cast iron crucible featuring a special coating for enhanced longevity.

PID Control System: Automatically regulates power output to optimize electricity use and reduce consumption.

Precise Temperature Control: Maintains zinc water temperature within ±2°C, ensuring high product quality and minimizing scrap rates.

Advanced Insulation: Built with high-quality thermal insulation materials for fast heating and excellent heat retention.

Accurate Temperature Measurement: Features ceramic-sheathed thermocouples for precise temperature measurement and extended durability.

Technical Specifications

- Electricity Consumption: Post-melting, uses 0.3 kWh per kilogram of zinc, with a capacity of 80-200 kilograms per hour.

- Heating Time: Reaches zinc charge temperature of 450°C in about 3 hours from start-up.

- Insulation Power Consumption: Normal insulation requires between 8 to 10 kWh per hour.

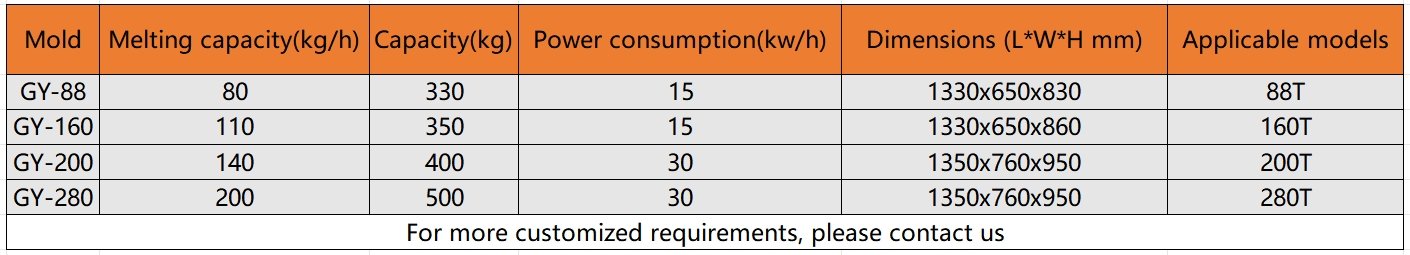

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.