Low Pressure Casting Insulation Furnace, an advanced industrial furnace

Low Pressure Casting Insulation Furnace, an advanced industrial furnace, is designed for maintaining aluminum temperatures during low-pressure casting. Featuring a crucible-free, melt pool-style construction, this furnace offers a range of advanced features for efficient and reliable operation.

Main Features

- Non-Iron Contamination: Industrial furnace Ensures aluminum liquid does not introduce iron, maintaining high casting quality.

- Robust Construction: The furnace shell is made from thick steel plates, welded for durability, pressure resistance, and long service life.

- Efficient Heating: Utilizes silicon-carbide rods for radiant heating, providing high thermal efficiency in a compact space.

- Precise Temperature Control: Equipped with a PID control system that adjusts current output based on actual temperature to ensure safety and energy efficiency.

- Advanced Insulation: Features high-quality ceramic fiber and nano insulation boards, minimizing heat loss and enhancing thermal retention.

- Safety Alarms: Includes alarms for over-temperature of aluminum liquid, furnace chamber, and pressure limits.

- Durable Lining: The melt pool-style furnace chamber is lined with high-temperature, non-stick aluminum materials from a reputable brand, ensuring over five years of service life.

- Capacity and Pressure: Rated for capacities from 150 to 3000 kg, with a maximum pressure resistance of 0.30 MPa.

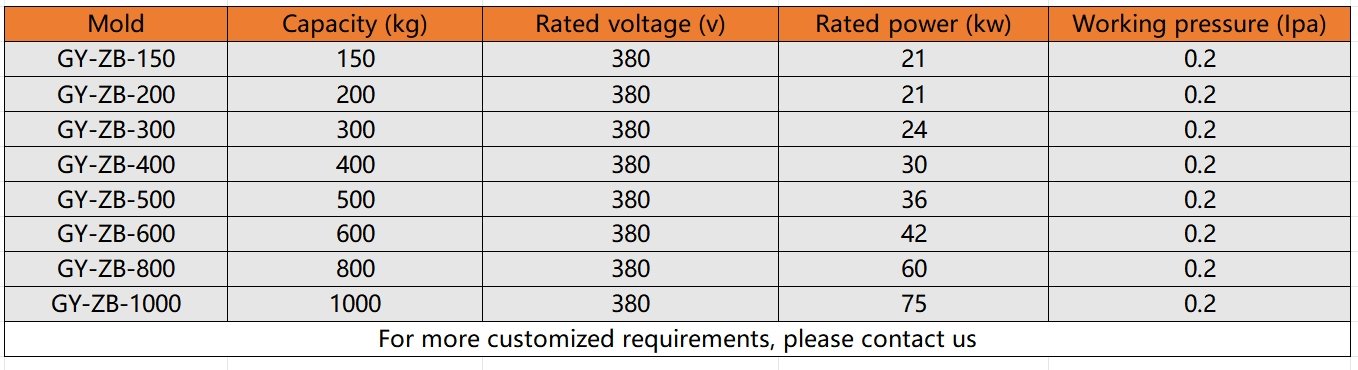

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.