Gas Engine Side Insulation Furnace uses natural gas as raw material and is mainly used in the side insulation furnace of aluminum alloy.(melting metal furnace)

Main Features

- Eco-Friendly Fuel: Melting metal furnace Utilizes natural gas or liquefied petroleum gas (LPG) as fuel, offering a green and environmentally friendly solution with high thermal efficiency.

- Durable Furnace Lining: Features a refractory lining made from imported brand casting materials, ensuring a lifespan of over five years. Resistant to aluminum adhesion, it eliminates the need for costly crucibles and prevents iron contamination.

- Advanced Insulation: Equipped with state-of-the-art nano thermal insulation materials that minimize heat loss and provide excellent insulation performance.

- Efficient Heating System: Includes an internationally branded radiant burner for complete combustion, effective heat radiation, and reduced aluminum loss.

- Energy Recovery: Incorporates a heat exchanger to recover and reuse thermal energy, enhancing energy efficiency and reducing fuel costs.

- Automated Control: Uses high-quality electrical components and PLC for stable, automated operation with easy controls.

- Convenient Maintenance: Features a furnace door on the side for easy cleaning and slag removal, simplifying maintenance.

- High-Quality Gas Components: All gas accessories and combustion fans are sourced from premium brands, ensuring safety, low noise, and minimal failure rates.

- Precise Temperature Measurement: Equipped with thermocouples for dual temperature measurement of molten aluminum and furnace atmosphere, maintaining temperature accuracy within ±5°C.

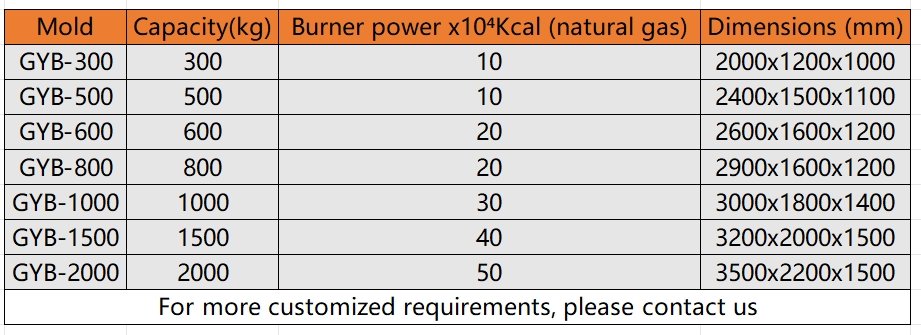

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.