Trimming Hydraulic Press (trim press)

Discover the Advantages of Trimming Hydraulic Press (trim press) ,We could supply not only custom machine,molds,robot arm(manipulator),auto feeder process technology, and other relative machines but also a full production line service.

Main Features

High-Speed Cylinder:

- Efficient Operation: Equipped with a built-in high-speed cylinder for rapid falling speeds and increased production efficiency.

Durable Construction:

- High-Strength Columns: Four columns made from high-strength alloy steel with a hard chrome-plated surface for superior abrasion resistance.

Adjustable Settings:

- Customizable Parameters: Pressure, stroke, and pressurizing time can be easily adjusted to meet specific processing requirements.

Optional Configurations:

- Enhanced Features: Includes protective shields, anti-drop devices, scrap removal systems, LED lighting, and infrared grating for improved functionality and safety.

Applications

Die Casting Operations:

- Vents Trimming and Shaping: Ideal for aluminum alloy and magnesium alloy die castings.

Industry Applications:

- Mobile Phones: Widely used in manufacturing aluminum and magnesium alloy components for mobile phones.

- Automotive and Motorcycle Parts: Effective for die casting parts in the automotive and motorcycle industries.

Metal and Non-Metal Parts:

- Shaping and Punching: Suitable for various metal and non-metal components.

Blanking Operations:

- Center and Side Blanking: Efficient for blanking operations.

Automation:

- Robotic Integration: Compatible with automatic robots for operation on large worktable machines.

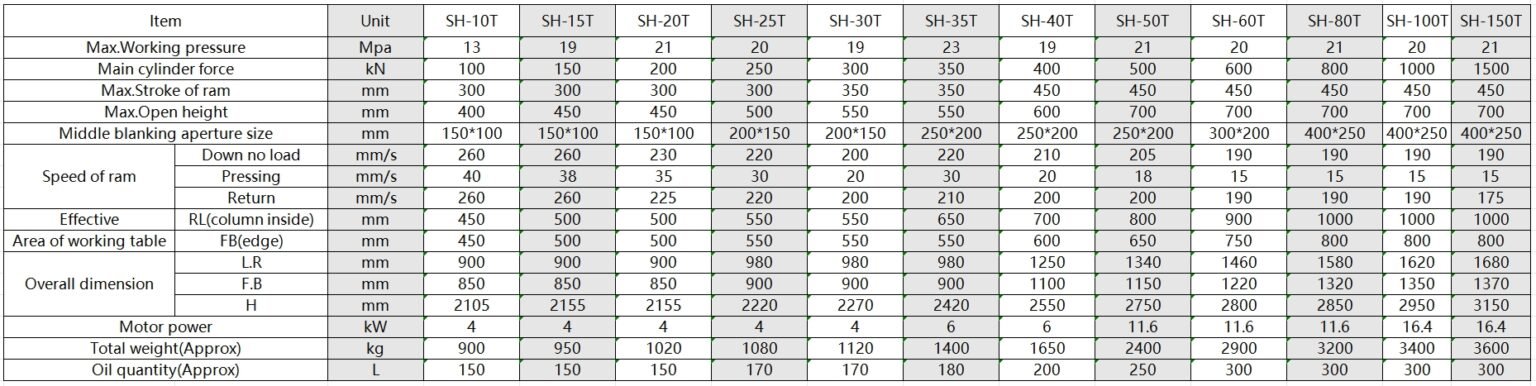

Equipment parameters

Achieving Excellence with SUMHONG

With Sumhong’s Integrated Die Casting System, manufacturers gain an all-in-one solution for precision and productivity. Our advanced system enhances every step of the process, delivering consistent quality and operational excellence.

Our Products

At SUMHONG, quality and innovation drive our ‘Integrated Die Casting System,’ where we bring tailored expertise across a wide range of equipment: deburring machines, die casting automation solutions, die casting furnaces, advanced die casting machines, fast die changing systems, and robust hydraulic presses.

Each solution is developed with a focus on reliability and efficiency, ensuring that our clients experience long-term success. Our dedication to customization and partnership cultivates mutual growth and sustainable production improvements.